Project Overview We successfully delivered a PLC controlled 10L jacketed glass reactor with lifting and tilting reaction vessel to a food processing client in the Philippines.This customized system was designed specifically for the concentration and ...

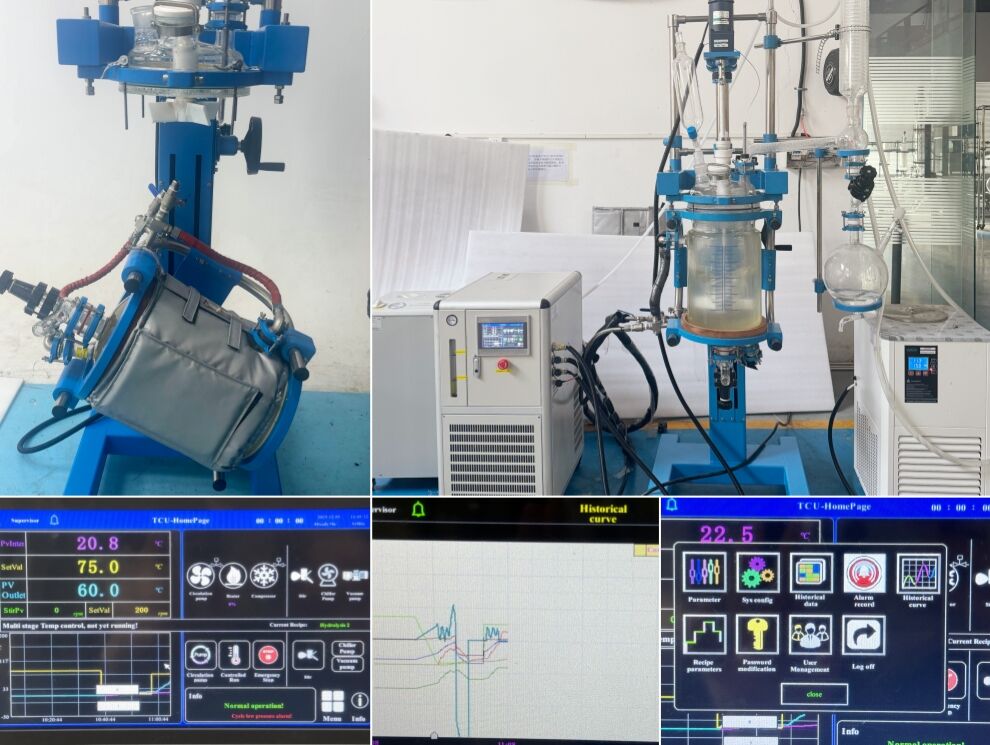

We successfully delivered a PLC controlled 10L jacketed glass reactor with lifting and tilting reaction vessel to a food processing client in the Philippines.

This customized system was designed specifically for the concentration and refinement of culinary sauces and seasonings, where precise temperature control, repeatability, and hygienic operation are critical.

By combining automated thermal management, recipe-based PLC control, and ergonomic reactor handling, the system ensures stable product quality while improving operational efficiency.

The client required a compact yet highly precise reactor solution for:

Controlled heating and cooling during sauce concentration

Consistent viscosity and flavor profile across batches

Easy material discharge and thorough cleaning

Full process traceability for quality control

The 10L jacketed glass reactor system was engineered to meet these needs while remaining scalable for future pilot or small-batch production.

At the heart of the system is a PLC-controlled heating and chilling circulator with an extended operating range of -35°C to 195°C.

This wide temperature span allows gentle heating, rapid cooling, and accurate temperature holding throughout the concentration process.

Key advantages include:

Stable jacket temperature control for sensitive food ingredients

Smooth transition between heating and cooling phases

Improved product consistency and reduced thermal degradation

The entire system is managed by a Siemens S7 PLC paired with a 10-inch touchscreen HMI, integrating all core functions into one intuitive control interface.

Operators can precisely set and monitor:

Reactor internal temperature

Stirring speed

Processing time

Alarm thresholds and safety limits

All process parameters are automatically recorded, supporting traceability and quality assurance requirements.

A standout feature of this system is its recipe management function.

Customized production recipes can be stored directly in the PLC

Each recipe automatically controls jacket temperature, cooling rate, and stirring parameters

Ensures excellent batch-to-batch reproducibility without manual adjustment

For added safety, the system is programmed to automatically pause operation if the temperature exceeds 110°C, protecting both the product and the equipment.

To improve usability and hygiene, the reactor is equipped with a lifting and tilting mechanism, allowing:

Easy material loading

Smooth and complete product discharge

Faster and more effective cleaning between batches

This ergonomic design is especially valuable in food and flavor applications where frequent cleaning is required.

In addition to controlling the reactor itself, the PLC system can also manage auxiliary equipment such as the vacuum pump, creating a fully integrated turnkey solution.

This intelligent automation enables the client to achieve:

Higher production efficiency

Greater process precision

Reliable scalability for future expansion

This PLC controlled 10L jacketed glass reactor with lifting and tilting vessel provides an ideal solution for food processing applications that demand precision, repeatability, and ease of operation.

It demonstrates our ability to deliver customized, automation-ready reactor systems tailored to specific process requirements.

For more information or to discuss your specific application needs,

please contact us at [email protected].

Our experienced engineering team is ready to support you with tailor-made glass reactor and automation solutions for food, pharmaceutical, and chemical processing.