high pressure stainless steel reactor

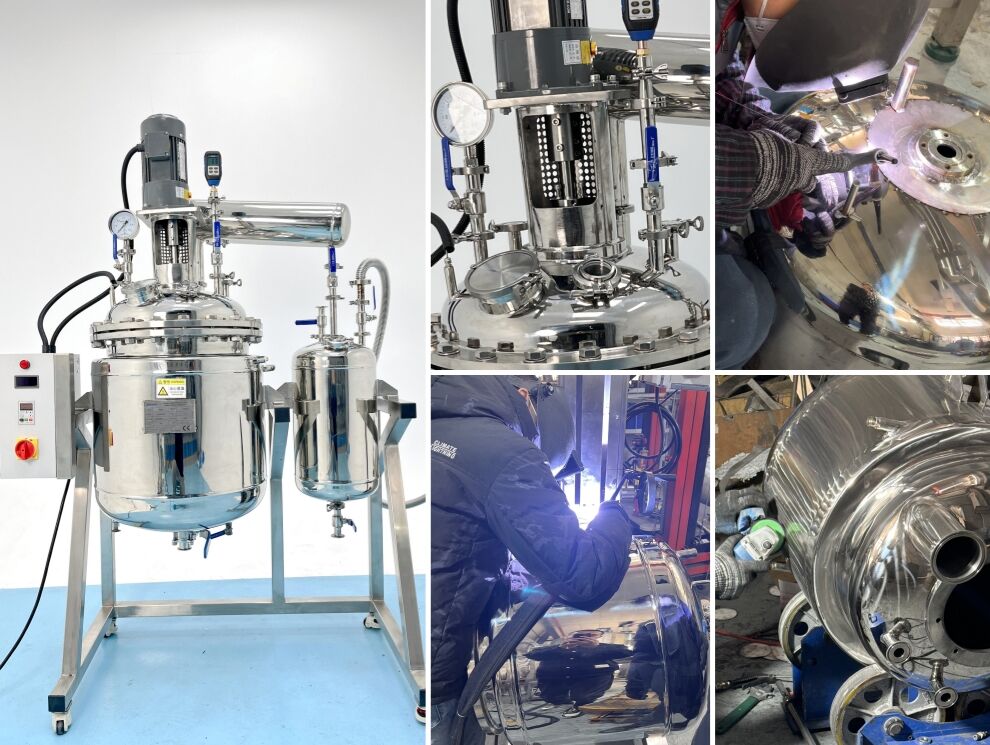

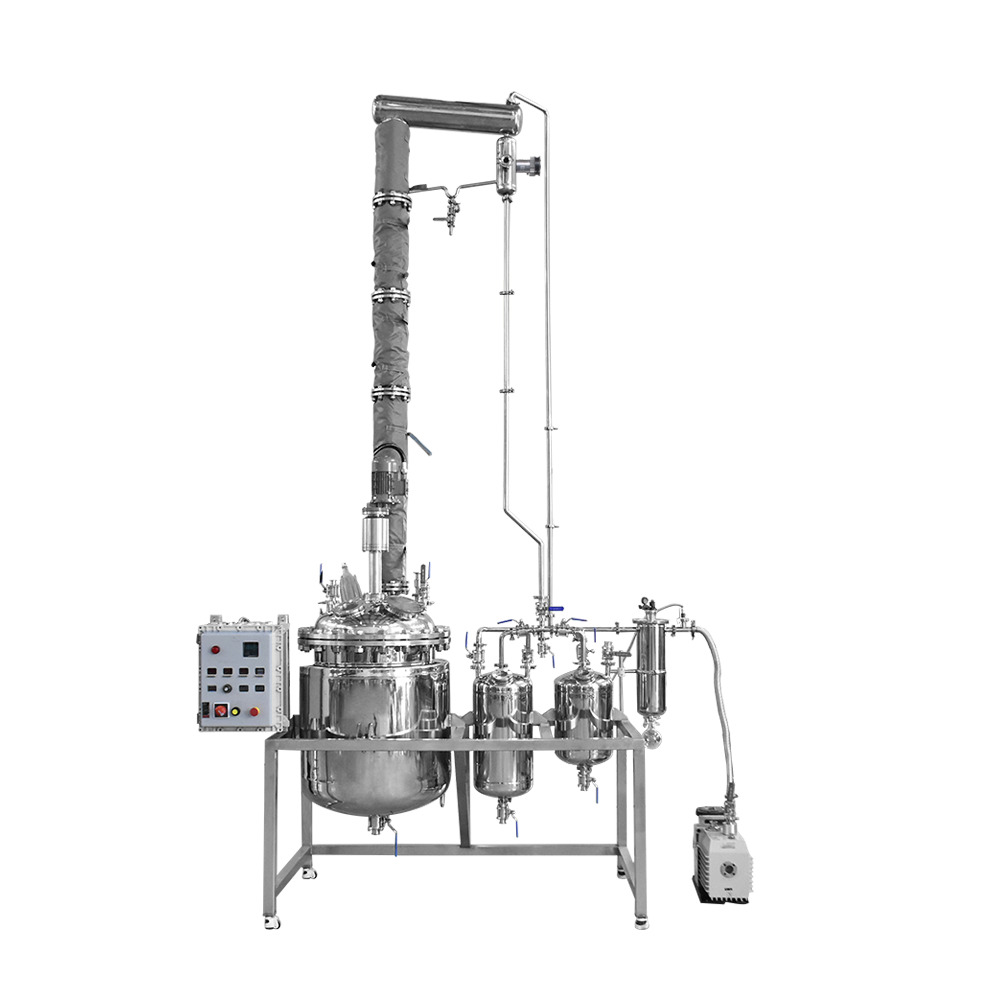

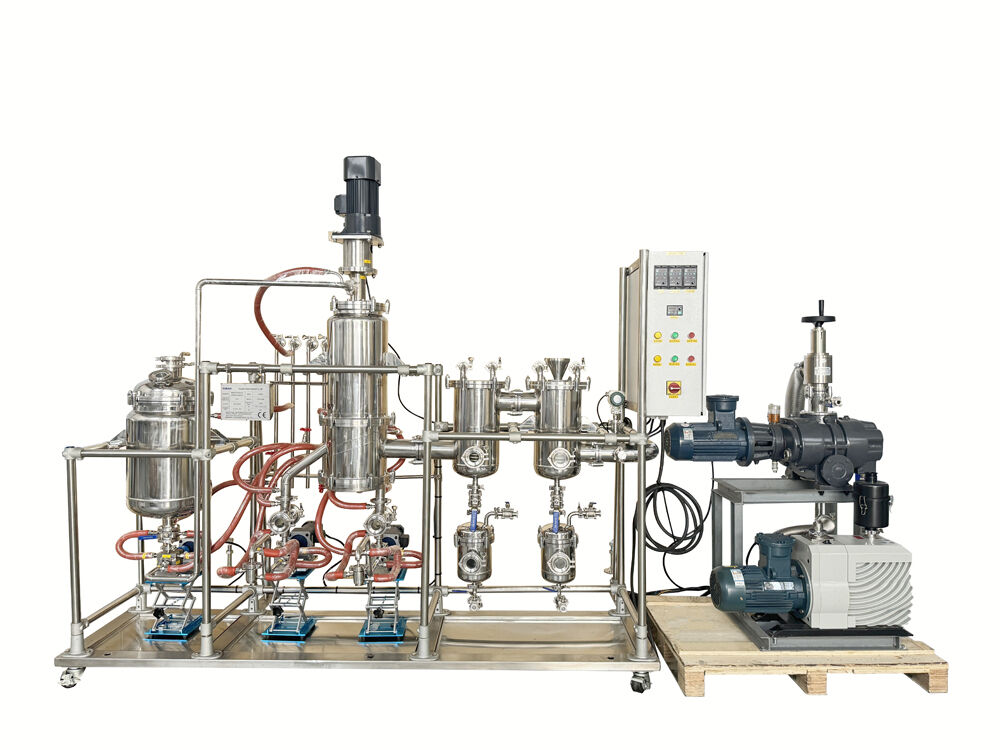

A high pressure stainless steel reactor represents a sophisticated piece of industrial equipment designed to facilitate chemical reactions under elevated pressure conditions while maintaining superior corrosion resistance and operational safety. These specialized vessels are engineered from premium-grade stainless steel alloys, typically 316L or 304 stainless steel, which provide exceptional durability and chemical compatibility across diverse processing environments. The primary function of a high pressure stainless steel reactor centers on enabling controlled chemical transformations that require pressurized atmospheres, ranging from moderate pressure applications to extreme high-pressure scenarios exceeding 1000 bar. The technological framework incorporates advanced pressure monitoring systems, temperature control mechanisms, and safety relief valves that work in unison to maintain optimal reaction parameters. These reactors feature precision-engineered pressure vessels with reinforced wall construction, ensuring structural integrity under demanding operational stress. The internal design typically includes specialized agitation systems, heating or cooling jackets, and multiple inlet and outlet ports for efficient material handling. Key technological features encompass digital pressure gauges, automated control systems, and robust sealing mechanisms that prevent leakage while maintaining process efficiency. Applications span numerous industries including pharmaceuticals, petrochemicals, specialty chemicals, food processing, and research laboratories. In pharmaceutical manufacturing, these reactors enable synthesis of active ingredients under sterile, controlled conditions. Petrochemical facilities utilize them for hydrogenation processes, polymerization reactions, and catalyst testing. The food industry employs these vessels for extraction processes, fermentation under pressure, and preservation techniques. Research institutions rely on high pressure stainless steel reactors for developing new materials, conducting reaction kinetics studies, and exploring novel synthetic pathways. The versatility of these systems makes them indispensable for any operation requiring precise pressure control combined with chemical resistance and operational reliability.