stainless steel pressure reactor

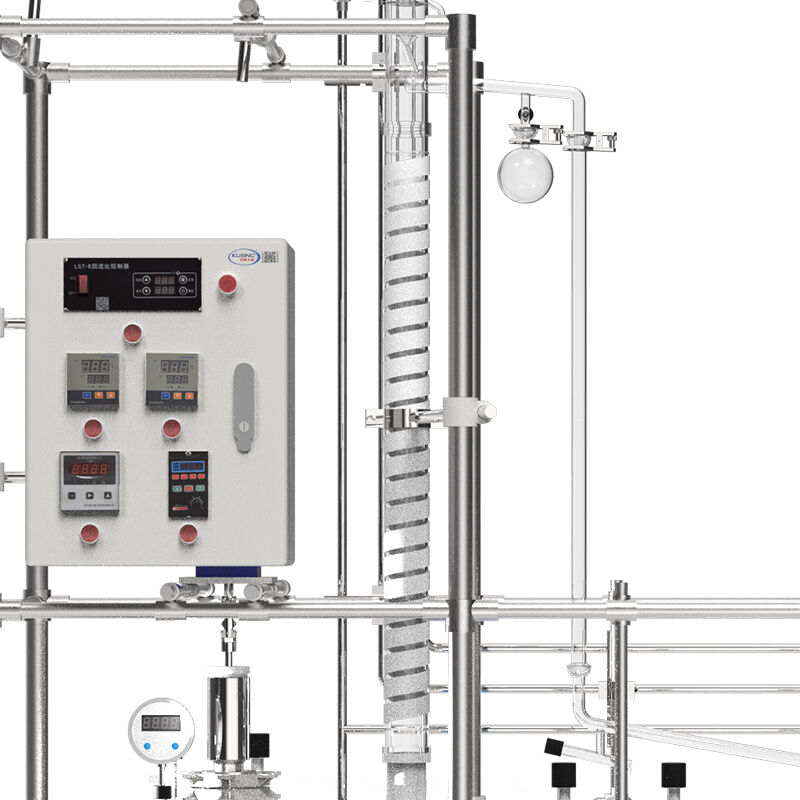

A stainless steel pressure reactor represents a crucial piece of equipment in modern chemical processing, pharmaceutical manufacturing, and industrial production facilities. This specialized vessel combines the exceptional corrosion resistance of stainless steel with advanced pressure containment technology to create a versatile solution for various chemical reactions and processing applications. The stainless steel pressure reactor operates by maintaining controlled pressure and temperature conditions within a sealed environment, enabling chemical reactions that would be impossible under normal atmospheric conditions. The main functions of this equipment include facilitating high-pressure chemical synthesis, conducting hydrogenation processes, performing polymerization reactions, and executing various pharmaceutical manufacturing procedures. The reactor's design incorporates sophisticated safety mechanisms, including pressure relief valves, temperature monitoring systems, and emergency shutdown protocols to ensure operator safety and process reliability. Technological features of the stainless steel pressure reactor encompass precision-engineered heating and cooling systems, advanced mixing mechanisms, and comprehensive monitoring instrumentation. The vessel typically includes multiple ports for reactant introduction, sampling, and gas purging, while maintaining hermetic sealing capabilities. Modern units feature computerized control systems that allow operators to precisely regulate temperature, pressure, and mixing parameters throughout the reaction cycle. Applications for stainless steel pressure reactors span numerous industries, including pharmaceutical drug development, specialty chemical production, petrochemical processing, and research laboratory operations. These reactors prove invaluable in manufacturing active pharmaceutical ingredients, producing high-performance polymers, creating specialty catalysts, and developing new materials under controlled conditions. The equipment supports both batch and semi-batch processing modes, accommodating diverse production requirements from small-scale research to large-scale commercial manufacturing operations.