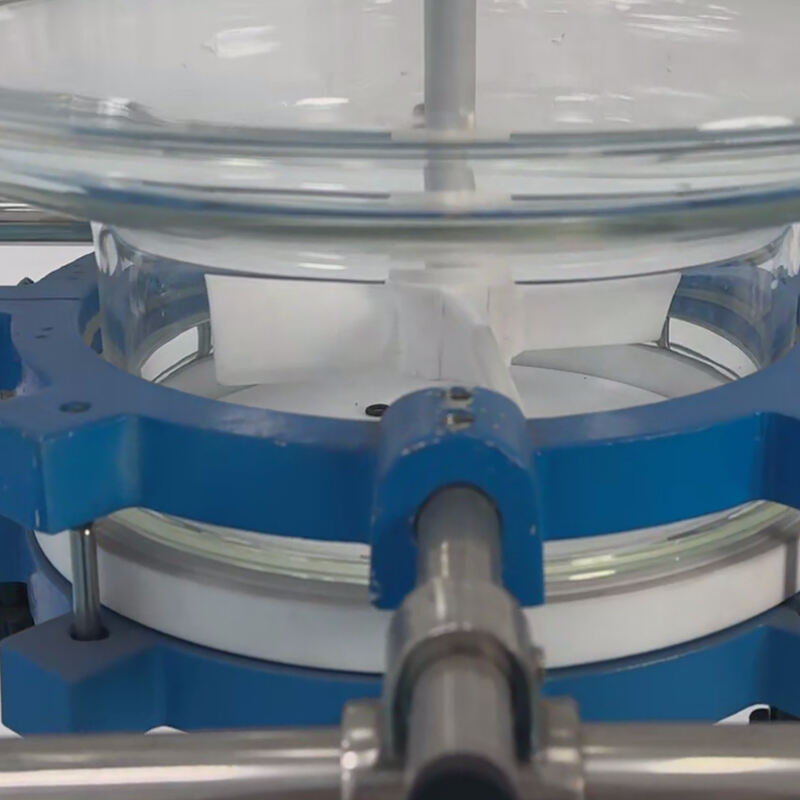

stainless steel mixing reactor

The stainless steel mixing reactor represents a cornerstone of modern industrial processing equipment, designed to facilitate controlled chemical reactions while ensuring superior product quality and operational safety. This sophisticated vessel combines robust construction with advanced mixing technology to deliver consistent results across diverse industrial applications. Built from high-grade stainless steel materials, these reactors offer exceptional resistance to corrosion, chemical attack, and temperature fluctuations, making them indispensable in pharmaceutical, chemical, food processing, and biotechnology industries. The primary function of a stainless steel mixing reactor involves creating homogeneous mixtures through precise agitation systems while maintaining optimal reaction conditions. These vessels incorporate multiple technological features including variable speed drives, temperature control systems, pressure monitoring capabilities, and customizable mixing configurations. The reactor design typically includes jacketed walls for heating or cooling applications, multiple inlet and outlet ports for raw material addition and product discharge, and comprehensive instrumentation for process monitoring and control. Advanced models feature programmable logic controllers that automate mixing sequences, ensuring reproducible batch quality and reducing operator intervention. The versatility of stainless steel mixing reactors extends to various processing scenarios, from simple blending operations to complex multi-phase reactions requiring precise environmental control. Their applications span pharmaceutical synthesis, polymer production, specialty chemical manufacturing, cosmetic formulation, and food ingredient processing. The seamless interior surfaces prevent product contamination while facilitating thorough cleaning procedures essential for maintaining sterile processing conditions. Modern stainless steel mixing reactor designs incorporate ergonomic features such as accessible maintenance points, easy-to-clean geometries, and modular component systems that simplify servicing and reduce downtime. These reactors serve as critical infrastructure for industries requiring consistent product quality, regulatory compliance, and operational efficiency in their manufacturing processes.