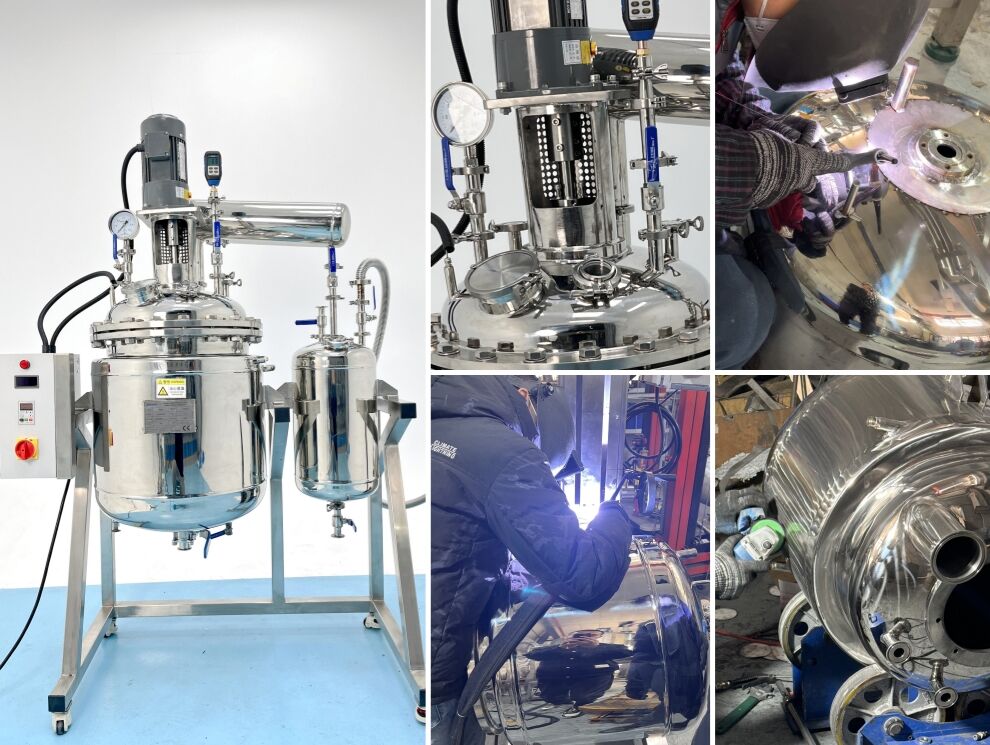

stainless steel high pressure reactor

A stainless steel high pressure reactor represents a sophisticated piece of industrial equipment designed to facilitate chemical reactions, material processing, and synthesis operations under elevated pressure and temperature conditions. This robust vessel combines the corrosion-resistant properties of stainless steel with advanced engineering to create a reliable platform for various industrial processes. The stainless steel high pressure reactor serves as the cornerstone of modern chemical manufacturing, pharmaceutical production, and materials science research. Its primary function involves containing and controlling chemical reactions that require pressurized environments to achieve optimal conversion rates, selectivity, and product quality. The reactor's stainless steel construction ensures exceptional durability and resistance to aggressive chemicals, making it suitable for handling corrosive substances that would damage conventional materials. Key technological features include precision pressure control systems, advanced temperature regulation mechanisms, and sophisticated mixing capabilities that ensure uniform reaction conditions throughout the vessel. The reactor incorporates safety systems such as pressure relief valves, temperature monitoring devices, and emergency shutdown protocols to protect operators and equipment. Its design typically features a cylindrical vessel with hemispherical or torispherical heads, providing optimal pressure distribution and structural integrity. The stainless steel high pressure reactor finds applications across diverse industries including petrochemicals, pharmaceuticals, food processing, specialty chemicals, and polymer manufacturing. In pharmaceutical applications, these reactors enable the synthesis of active pharmaceutical ingredients under controlled conditions. The petrochemical industry utilizes them for hydrogenation, polymerization, and catalytic processes. Food processors employ these reactors for sterilization, extraction, and concentration operations. The reactor's versatility extends to research and development environments where scientists explore new reaction pathways and optimize process parameters. Advanced models feature computerized control systems that monitor and adjust operational parameters in real-time, ensuring consistent product quality and process efficiency. The stainless steel construction provides excellent cleanability, making these reactors ideal for applications requiring stringent hygiene standards.