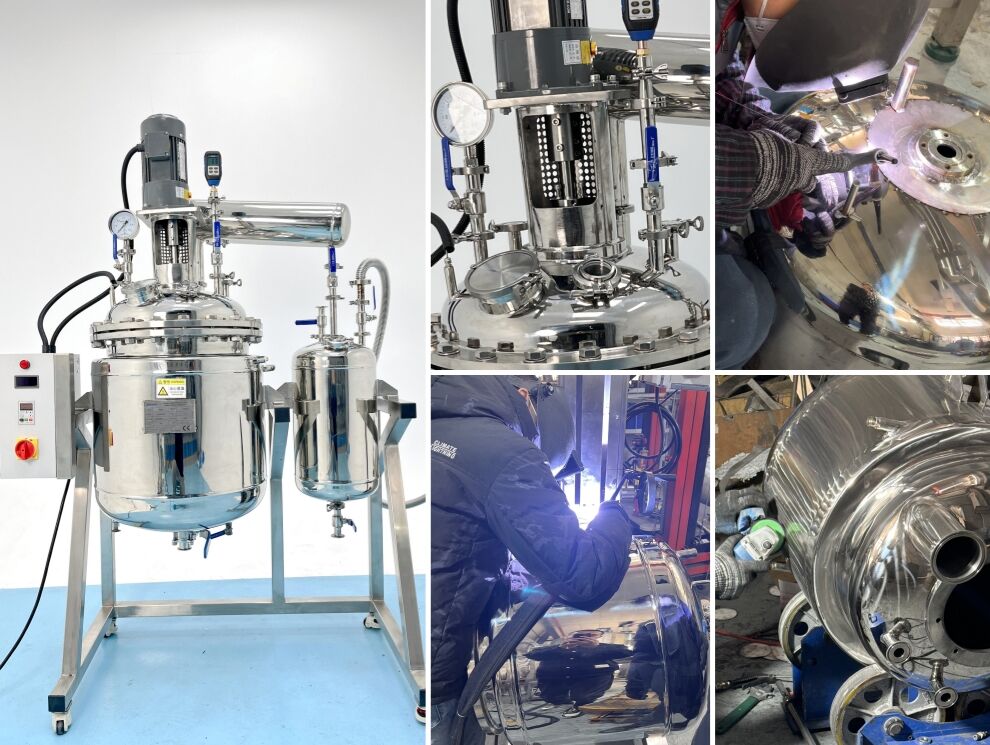

stainless steel emulsifying reactor

A stainless steel emulsifying reactor represents a sophisticated piece of industrial equipment designed to create stable emulsions, suspensions, and homogeneous mixtures across various manufacturing sectors. This specialized reactor combines the durability and hygienic properties of stainless steel construction with advanced mixing technologies to deliver consistent, high-quality results in production environments. The primary function of a stainless steel emulsifying reactor involves breaking down particles and droplets to create uniform distributions within different phases of materials, ensuring optimal product consistency and stability. These reactors utilize high-shear mixing principles, incorporating rotor-stator systems that generate intense mechanical forces to achieve thorough emulsification. The technological features of modern stainless steel emulsifying reactors include variable speed controls, temperature regulation systems, and precise monitoring capabilities that allow operators to maintain optimal processing conditions throughout production cycles. These units typically feature jacketed designs for heating or cooling applications, enabling temperature-sensitive formulations to be processed safely and effectively. The robust construction ensures longevity while meeting stringent hygiene standards required in pharmaceutical, food, and cosmetic industries. Applications for stainless steel emulsifying reactors span numerous industries, including pharmaceutical manufacturing for creating ointments, creams, and liquid medications, food processing for producing mayonnaise, sauces, and dairy products, and cosmetic production for formulating lotions, creams, and beauty products. Chemical processing facilities utilize these reactors for creating paints, adhesives, and specialty chemical formulations. The versatility of stainless steel emulsifying reactors makes them indispensable in research and development laboratories where small-batch testing and formulation development occur. These reactors accommodate various viscosities and can handle both oil-in-water and water-in-oil emulsions, providing manufacturers with flexible processing solutions that adapt to diverse product requirements and production scales.