Why Stainless Steel Extraction Reactors Last Longer

Typical Lifespan of Stainless Steel Reactors in Industrial Applications

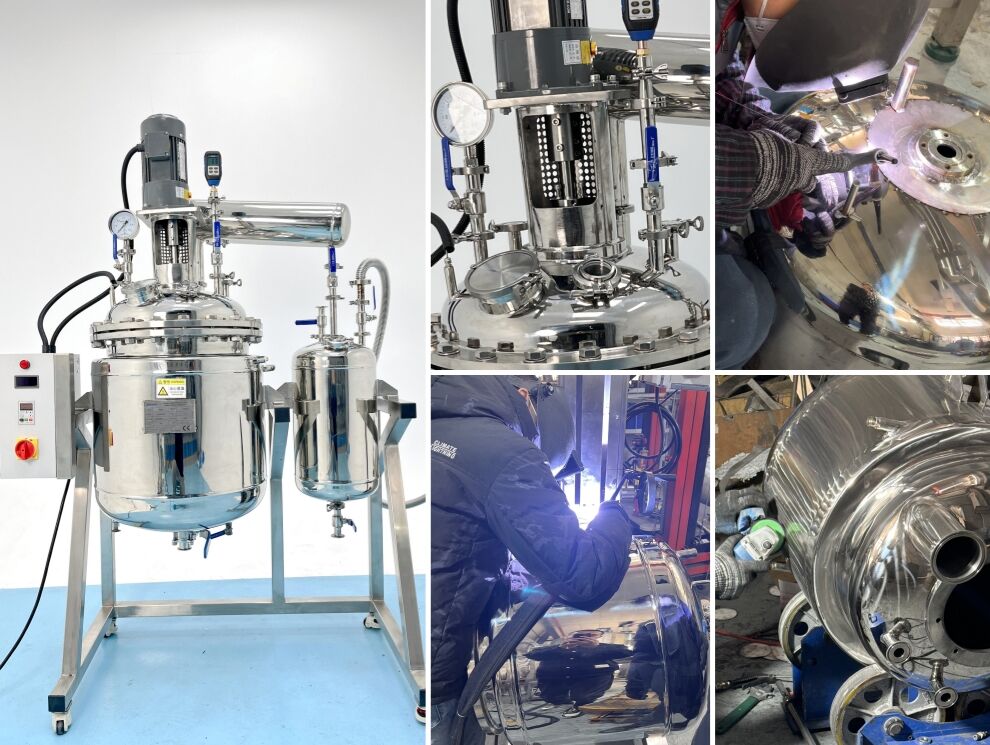

Industrial stainless steel extraction reactors built to last decades in tough environments aren't uncommon these days. The big ones typically keep running strong for around 30 to 50 years straight without major issues. According to recent data from the chemical processing sector, reactors that get regular maintenance checks still hold about 92% of their original strength even after quarter century of constant contact with harsh acidic solutions. What makes stainless steel so tough? Well, it naturally fights off corrosion better than most metals, handles temperature fluctuations without warping, and stands up to physical wear and tear far longer than cheaper alternatives. These properties explain why many plants stick with stainless despite higher upfront costs when compared to other reactor materials.

Comparative Durability: Stainless Steel vs. Glass-Lined and Carbon Steel Reactors

| Material | Average Lifespan | Key Vulnerability |

|---|---|---|

| Stainless Steel | 30–50 years | None (passivation layer) |

| Glass-Lined Steel | 10–15 years | Thermal shock cracking |

| Carbon Steel | 5–8 years | Oxidation/pitting |

Analyses of chemical processing plants show stainless steel reactors require 63% fewer unplanned replacements than glass-lined systems, primarily because they withstand rapid temperature changes exceeding 200°C/min without damage. In chloride-rich environments, carbon steel exhibits a corrosion rate 3.8 times higher than stainless steel, drastically shortening its operational life.

Real-World Data on Long-Term Performance Under Continuous Operation

Over the course of ten years studying pharmaceutical extraction systems, it became clear that stainless steel reactors maintained impressive uptime at around 98.4%, way ahead of what composite material vessels managed at just 76.2%. People working on these systems pointed to something called the stable chromium oxide passivation layer as the main reason behind this reliability. This protective layer cut down particulate contamination problems by about 87% when compared against glass lined options. Looking specifically at terephthalic acid production facilities, field measurements indicated wall thickness losses remained under 0.1% per year for 316L stainless steel reactors. That kind of durability supports expectations that these reactors could last well past four decades before needing replacement, making them a smart long term investment for manufacturers concerned about both quality control and operational costs.

Corrosion Resistance: The Core of Stainless Steel Durability

How Stainless Steel Resists Corrosion in Aggressive Chemical Environments

Stainless steel stays durable because it creates its own protective coating made of chromium oxide whenever it touches air. This thin layer acts as armor against problems like chloride pitting and crevice corrosion, even when things get really harsh - we're talking about super acidic environments where pH levels drop between 1 and 4, or situations where temperatures climb past 150 degrees Celsius. Regular carbon steel just can't handle this kind of abuse, typically breaking down at around 0.1 to 0.2 millimeters per year in such conditions. But stainless steel? Its corrosion rate drops way below 0.01 mm/year in almost all industrial solvents. That makes it a much better choice for equipment that needs to last through tough chemical processes without constant replacement.

Role of Chromium and Nickel in Forming a Stable Passive Layer

The chromium content needs to be at least 10.5% to start forming that protective oxide layer on the surface. Nickel plays its part too, helping keep the metal structure stable when it goes through those temperature changes over time. Now molybdenum is where things get interesting, especially in grades like 316L stainless steel. This element makes a big difference against chloride corrosion, cutting down on cracks that can form in harsh environments. Some tests show this protection works much better than regular alloys without molybdenum, though exact numbers vary depending on conditions. What matters most is that these combined elements allow the passive layer to keep rebuilding itself again and again, no matter how many times technicians clean equipment or expose it to chemicals during normal operations.

Chemical Compatibility With Common Solvents and Extraction Reagents

Stainless steel is highly compatible with a wide range of process fluids:

- Hydrochloric acid (up to 5% concentration at 25°C)

- Ethanol and acetone (full concentration, ≤80°C)

- Alkaline solutions (pH ≤13, including sodium hydroxide)

For more aggressive applications, grade 904L extends compatibility to phosphoric and sulfuric acids, resisting intergranular corrosion three times longer than 316L in FDA-regulated extraction processes.

High Initial Cost vs. Long-Term Savings From Reduced Corrosion Damage

Stainless steel reactors do cost about 20 to 30 percent more initially compared to glass lined options, but they last so much longer that it actually saves money in the long run. Most facilities find these reactors can operate continuously for well over 25 years in pharmaceutical settings. When looking at the whole picture, stainless steel ends up costing around 40 to 60 percent less overall during its lifetime. A recent study from 2023 looked at this exact thing and found that companies saved approximately seven hundred forty thousand dollars per reactor just by avoiding all those expensive shutdowns caused by corrosion issues over twenty years.

Performance Comparison of 316L, 904L, and Other Grades in Extraction Processes

The performance of stainless steel reactors really depends on their specific alloy composition. Take Grade 316L for example. This grade contains between 2 and 3 percent molybdenum along with very low carbon levels under 0.03%. What makes this material so valuable is its ability to resist corrosion from chlorides, which is why many manufacturers prefer it when dealing with saltwater based extraction processes in pharmaceutical production. Plus, there's another benefit worth mentioning too. The low carbon content actually helps prevent what's called sensitization problems when these reactors need to be welded together. Now if we look at alternative materials like 904L stainless steel, things get interesting but come at a price. While 904L stands up much better against sulfuric acid especially when exposed to high temperatures, making it great for certain specialty chemical applications, companies should know they'll pay anywhere from 40 to 60 percent more for this enhanced protection compared to standard options.

Microstructural Properties That Improve Fatigue and Stress Resistance

Austenitic grades like 316L derive enhanced durability from their face-centered cubic crystalline structure, which provides:

- 25–30% higher fatigue strength than ferritic steels

- Improved resistance to stress corrosion cracking due to 10–14% nickel content

Fine-grained variants produced through controlled rolling demonstrate 15–20% greater tolerance to cyclic loading—critical for reactors subjected to frequent pressure fluctuations.

Behavior Under Thermal Cycling and Repeated Pressure Loads

Stainless steel maintains dimensional stability across thousands of thermal cycles. For example, 316L shows less than 0.1% permanent deformation after 10,000 cycles between 25°C and 250°C. Its thermal expansion coefficient (16.5 μm/m°C) closely matches common internal linings, minimizing interfacial stress during rapid heating or cooling.

How Material Quality Influences Long-Term Reactor Integrity

The purity of materials really matters when it comes to how they perform over time. When looking at 316L alloys that don't meet standards, tests show these can develop cracks three times faster during ASTM G48 evaluations because of those pesky impurities getting in the way. Research from metallurgists tells us something interesting too. Vacuum arc remelting creates VAR steels that last reactors about 12 to maybe even 15 extra years compared to regular air melted versions. That might seem like a big upfront expense but think about all the money saved later on with fewer repairs needed and no unexpected failures causing downtime or safety issues down the road.

Operating Conditions and Their Effect on Reactor Durability

Safe Operation Under High Temperature and High-Pressure Conditions

Stainless steel reactors can handle temperatures as high as around 600 degrees Celsius (which is roughly 1,112 Fahrenheit) and pressures over 150 bar or about 2,175 pounds per square inch. The material's good thermal conductivity properties for grade 316L stainless steel (around 16 watts per meter kelvin) means heat spreads out pretty evenly across surfaces, which cuts down on hot spots that could cause problems. At operating temperatures near 500 degrees Celsius, this type of stainless still holds onto most of its strength, specifically about 930 megapascals of proof strength, so it won't start to deform under pressure over time. Most engineers build in extra capacity when designing these systems, usually somewhere between 20 to 30 percent beyond what calculations suggest, just to be safe given how unpredictable raw materials can sometimes behave during processing.

Impact of Thermal Fluctuations and Pressure Cycles on Structural Health

Repeated thermal cycling between 50°C and 400°C increases fatigue crack growth by 40%, according to ASM International (2022). Operating above 25% of design pressure limits can shorten reactor lifespan by 7–12 years. Modern strain monitoring systems detect microstructural changes with 0.01mm precision, enabling proactive maintenance before critical failures occur.

Maintaining Passivation Layer Stability During Prolonged Chemical Exposure

The chromium-rich passive layer (2–5nm thick) remains effective within pH 1.5–13 when chloride levels stay below 25 ppm. A 2023 corrosion study showed 904L retains 98% passivation effectiveness after 10,000 hours in 70% sulfuric acid at 80°C—outperforming glass-lined reactors by 37% in aggressive environments.

Balancing Performance and Durability When Pushing Operational Limits

Operating at 90% of maximum capacity typically reduces reactor lifespan from 35 to 17 years. To optimize performance and longevity, operators implement:

- Real-time wall thickness monitoring (0.1mm accuracy)

- Adaptive temperature ramping (≤5°C/minute)

- Predictive AI models that reduce emergency shutdowns by 63%

Maximizing Lifespan: Maintenance and Economic Benefits

Best practices for inspection, cleaning, and corrosion monitoring

Doing regular ultrasonic thickness checks along with visual inspections at around 500 operating hours can cut down on wall thinning issues by approximately 40% when compared to those random, inconsistent maintenance routines we see so often (according to NACE International in their 2023 report). When it comes to keeping equipment surfaces protected, automated cleaning combined with occasional electropolishing works wonders for maintaining that all important passive layer. This approach actually makes the material twice as resistant to corrosion compared to old school nitric acid baths which just don't hold up as well anymore. And let's not forget about ATP bioluminescence testing either. This method gets rid of contaminants at an impressive rate of nearly 99.9%, something regular visual checks simply cannot match no matter how carefully someone looks.

| Maintenance Factor | Traditional Approach | Optimized Practice | Result Improvement |

|---|---|---|---|

| Inspection Frequency | Annual | Biannual + sensors | 68% defect detection rate ⌠ |

| Passivation Method | Nitric acid baths | Electropolishing | 2X corrosion resistance ⌠ |

| Cleaning Validation | Visual confirmation | ATP bioluminescence | 99.9% contaminant removal |

Proactive maintenance aligned with equipment stress profiles reduces lifetime repair costs by 20–35% in pharmaceutical extraction systems.

Predictive maintenance strategies to extend service life

Integrating vibration analysis with machine learning predicts agitator bearing failures 120–150 hours in advance. Thermal imaging during operation detects hot spots 30% faster than manual inspections, extending refractory lining life by an average of 18 months (Institution of Mechanical Engineers 2022).

Total cost of ownership: Long-term savings of durable stainless steel reactors

Despite a 25–30% higher initial investment, stainless steel reactors deliver 50% lower lifetime costs over a 15-year period. A 2023 study across 72 chemical plants demonstrated substantial savings:

| Cost Category | Carbon Steel Reactors | 316L Stainless Reactors | Lifetime Savings |

|---|---|---|---|

| Corrosion repairs | $1.2M | $240k | $960k (80%) |

| Downtime penalties | $580k | $85k | $495k (85%) |

| Replacement cycles | 3.4 | 1.2 | 64% reduction |

These efficiencies allow stainless steel reactors to achieve return on investment within 5–7 years, compared to 8–10 years for alternative materials in continuous extraction environments.

FAQ Section

What is the typical lifespan of stainless steel extraction reactors?

Industrial stainless steel extraction reactors can last between 30 to 50 years under optimal conditions with regular maintenance.

How does stainless steel compare to other materials like glass-lined and carbon steel reactors?

Stainless steel reactors generally offer better durability and resistance to corrosion compared to glass-lined and carbon steel reactors, leading to fewer replacements and lower maintenance costs.

What role does the chromium oxide layer play?

The chromium oxide layer acts as a protective shield against corrosion, significantly prolonging the lifespan of stainless steel reactors.

Why is stainless steel considered a cost-effective choice despite a higher initial investment?

While stainless steel reactors have a higher upfront cost, their resistance to corrosion and longer operational lifespan result in lower maintenance costs and fewer replacements, making them a cost-effective choice over time.

Table of Contents

- Why Stainless Steel Extraction Reactors Last Longer

- Corrosion Resistance: The Core of Stainless Steel Durability

- Performance Comparison of 316L, 904L, and Other Grades in Extraction Processes

- Operating Conditions and Their Effect on Reactor Durability

- Maximizing Lifespan: Maintenance and Economic Benefits

-

FAQ Section

- What is the typical lifespan of stainless steel extraction reactors?

- How does stainless steel compare to other materials like glass-lined and carbon steel reactors?

- What role does the chromium oxide layer play?

- Why is stainless steel considered a cost-effective choice despite a higher initial investment?