Versatile Multi-Industry Application Capabilities

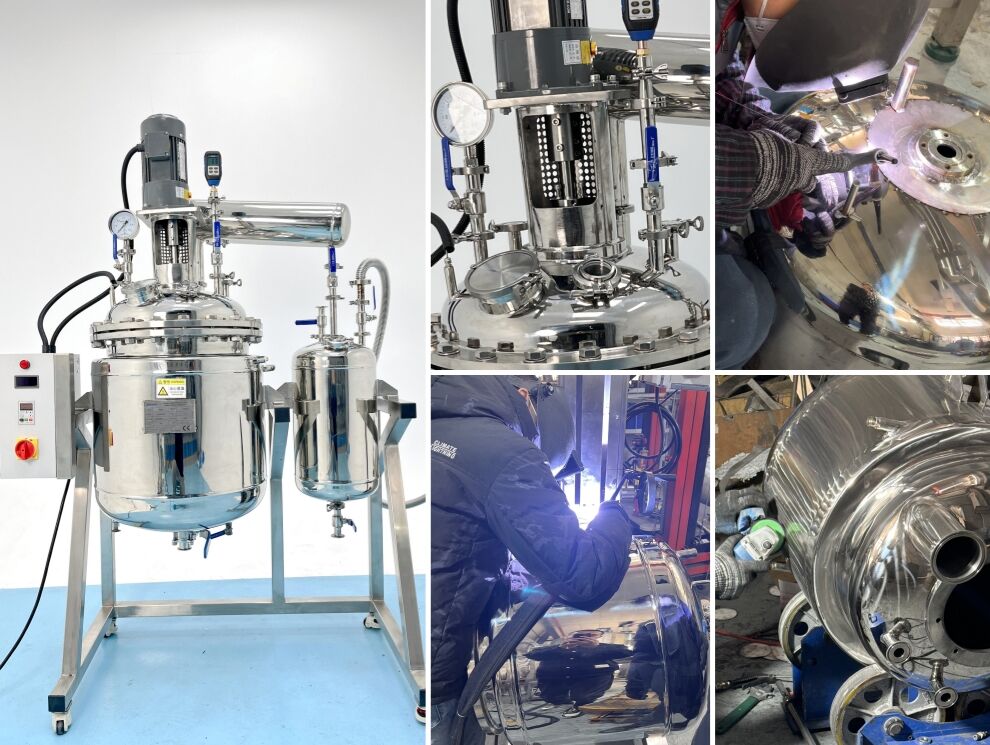

The extraction reactor with filter demonstrates remarkable versatility through its ability to serve diverse industries with varying processing requirements, making it an invaluable investment for companies seeking flexible, adaptable processing solutions. This adaptability stems from the system's modular design architecture and customizable configuration options that allow optimization for specific applications while maintaining the fundamental advantages of integrated extraction and filtration processes. In pharmaceutical manufacturing, the extraction reactor with filter excels at producing high-purity active pharmaceutical ingredients through precise control of extraction parameters and continuous removal of impurities that could affect drug efficacy or safety. The system's ability to maintain sterile conditions and provide comprehensive documentation makes it ideal for meeting stringent regulatory requirements imposed by agencies such as the FDA and EMA. Food and beverage industries benefit from the extraction reactor with filter's capability to process natural ingredients while preserving delicate flavor compounds and nutritional components. The system can extract essential oils, natural colorants, and bioactive compounds from plant materials while ensuring food-grade cleanliness and avoiding contamination. Chemical processing applications utilize the extraction reactor with filter for separating valuable compounds from complex reaction mixtures, recovering solvents, and purifying intermediate products. The system's chemical compatibility ensures reliable operation with aggressive solvents and corrosive materials. Environmental applications leverage the extraction reactor with filter for soil remediation projects, groundwater treatment, and waste processing operations, where precise separation of contaminants from environmental media is crucial for restoration success. The system's robust construction and contamination-resistant design make it suitable for challenging environmental conditions. Biotechnology companies employ the extraction reactor with filter for purifying biological products, separating cellular components, and concentrating valuable biomolecules while maintaining biological activity. Research and development organizations appreciate the system's scalability, which enables seamless transition from laboratory-scale experiments to pilot production and eventually full-scale manufacturing. The extraction reactor with filter can process various feed materials including liquids, slurries, and dissolved solids, while accommodating different extraction media such as organic solvents, supercritical fluids, and aqueous solutions. This flexibility eliminates the need for multiple specialized systems, reducing capital investment and operational complexity. Customization options include specialized materials of construction for chemical compatibility, enhanced automation for unmanned operation, and specialized filtration media for unique separation challenges, ensuring that each extraction reactor with filter installation delivers optimal performance for its intended application.