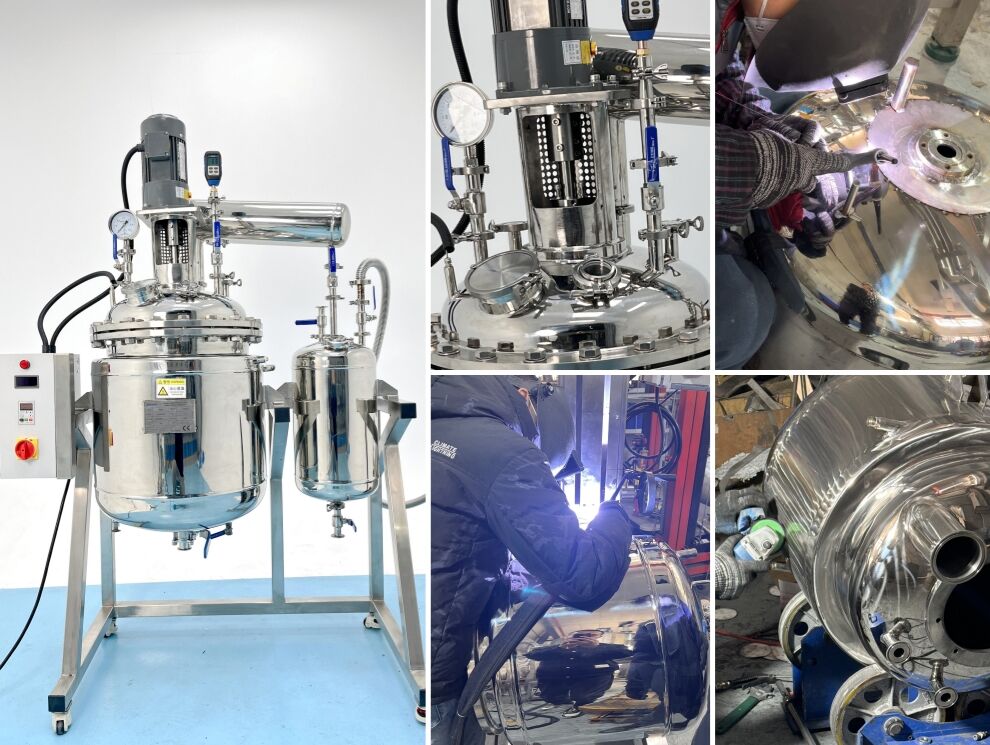

solvent extraction reactor

A solvent extraction reactor represents a sophisticated piece of industrial equipment designed to facilitate the separation and purification of valuable compounds through liquid-liquid extraction processes. This advanced system operates by utilizing the differential solubility properties of various substances in different solvents, enabling efficient separation of target materials from complex mixtures. The solvent extraction reactor serves as the cornerstone of numerous industrial processes, particularly in pharmaceutical manufacturing, chemical processing, metallurgy, and environmental remediation applications. The reactor's primary function involves creating optimal conditions for mass transfer between two immiscible liquid phases, typically an aqueous phase and an organic solvent phase. Through controlled mixing and subsequent separation, the solvent extraction reactor enables selective extraction of desired compounds while leaving unwanted impurities behind. Modern solvent extraction reactor designs incorporate advanced features such as temperature control systems, automated pH adjustment mechanisms, and precise flow rate regulation to ensure consistent extraction efficiency. The technological framework of these reactors includes robust mixing mechanisms that create intimate contact between phases while maintaining the ability to achieve clean phase separation afterward. Many solvent extraction reactor units feature modular construction, allowing for scalability from laboratory-scale operations to full industrial production capacity. The reactor's versatility extends to handling various solvent systems, accommodating both batch and continuous processing modes depending on specific application requirements. Safety considerations remain paramount in solvent extraction reactor design, with integrated containment systems, vapor recovery units, and explosion-proof electrical components ensuring secure operation. These reactors often incorporate advanced monitoring systems that provide real-time feedback on extraction performance, enabling operators to optimize process parameters for maximum efficiency and product quality.