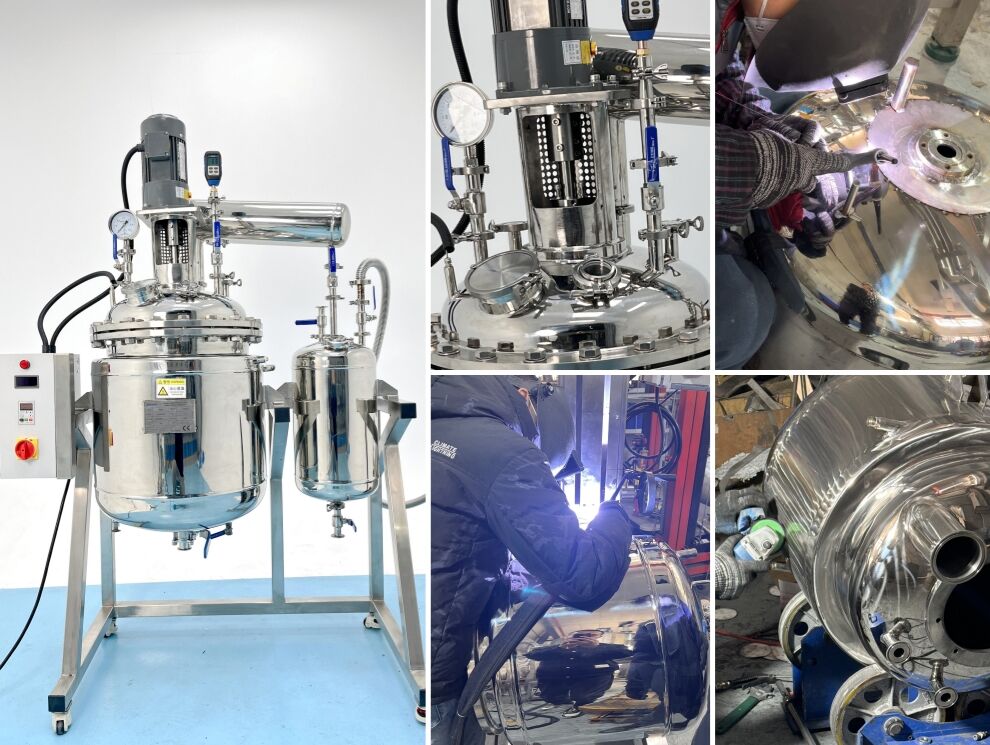

extraction reactor for purification

An extraction reactor for purification represents a sophisticated chemical processing system designed to separate and purify target compounds from complex mixtures through liquid-liquid extraction processes. This advanced equipment serves as the cornerstone of modern purification technologies, offering precise control over mass transfer operations while maintaining optimal efficiency standards. The extraction reactor for purification operates on fundamental principles of solvent extraction, where selective solvents remove specific components from feed streams based on their chemical affinity and solubility characteristics. The main functions of this extraction reactor for purification include continuous separation of valuable compounds, removal of impurities from process streams, and concentration of desired products to meet strict quality specifications. The system incorporates multiple stages of counter-current flow patterns, ensuring maximum contact between phases while minimizing solvent consumption. Technological features of the extraction reactor for purification encompass advanced mixing mechanisms, temperature control systems, and automated monitoring capabilities that guarantee consistent performance across various operating conditions. The reactor design typically includes specialized internals such as structured packing, rotating discs, or pulsed columns that enhance mass transfer rates and separation efficiency. Applications for the extraction reactor for purification span across pharmaceutical manufacturing, where active pharmaceutical ingredients require high-purity standards, chemical processing industries for specialty chemical production, and environmental remediation projects involving contaminated water treatment. The extraction reactor for purification also finds extensive use in metallurgical operations for metal recovery, food processing for flavor extraction, and biotechnology applications for protein purification. Modern versions incorporate digital control systems, real-time monitoring sensors, and predictive maintenance capabilities that optimize operational performance while reducing downtime and maintenance costs.