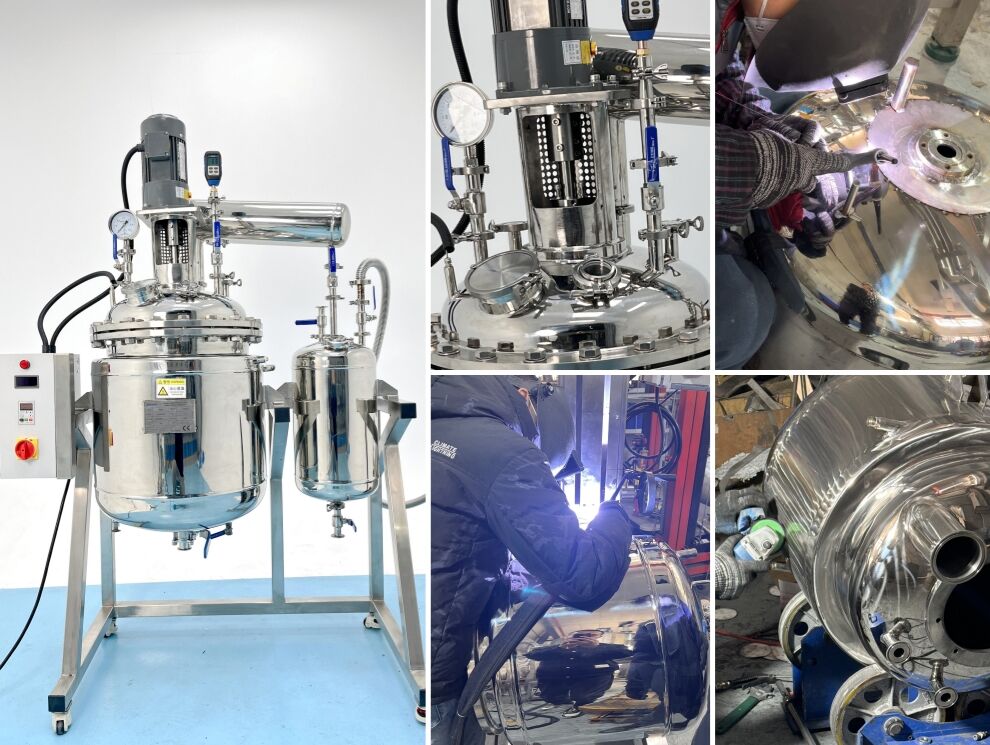

chemical extraction reactor

A chemical extraction reactor represents a sophisticated industrial processing unit designed to facilitate the separation and purification of specific compounds from complex mixtures through advanced extraction methodologies. This specialized equipment serves as the cornerstone for numerous manufacturing processes across pharmaceutical, petrochemical, food processing, and biotechnology industries. The primary function of a chemical extraction reactor involves creating optimal conditions for mass transfer operations, where target substances are selectively removed from their original matrices using appropriate solvents or extraction media. The reactor's design incorporates multiple stages of contact between the feed material and extraction medium, ensuring maximum efficiency in compound recovery. Key technological features include precise temperature control systems, adjustable mixing mechanisms, and sophisticated separation chambers that maintain consistent processing conditions throughout the extraction cycle. The equipment typically features corrosion-resistant materials such as stainless steel or specialized alloys to withstand aggressive chemical environments. Advanced monitoring systems continuously track parameters like pH levels, temperature gradients, and concentration profiles to optimize extraction performance. Modern chemical extraction reactors integrate automated control systems that adjust operational variables in real-time, ensuring consistent product quality and maximizing yield rates. The versatile design accommodates various extraction techniques including liquid-liquid extraction, solid-liquid extraction, and supercritical fluid extraction depending on specific application requirements. These reactors find extensive applications in pharmaceutical manufacturing for active ingredient isolation, essential oil production in the cosmetics industry, metal recovery in mining operations, and purification processes in chemical manufacturing. The scalable nature of chemical extraction reactor designs allows for seamless transition from laboratory-scale research to full production implementation, making them invaluable tools for process development and commercial manufacturing operations across diverse industrial sectors.