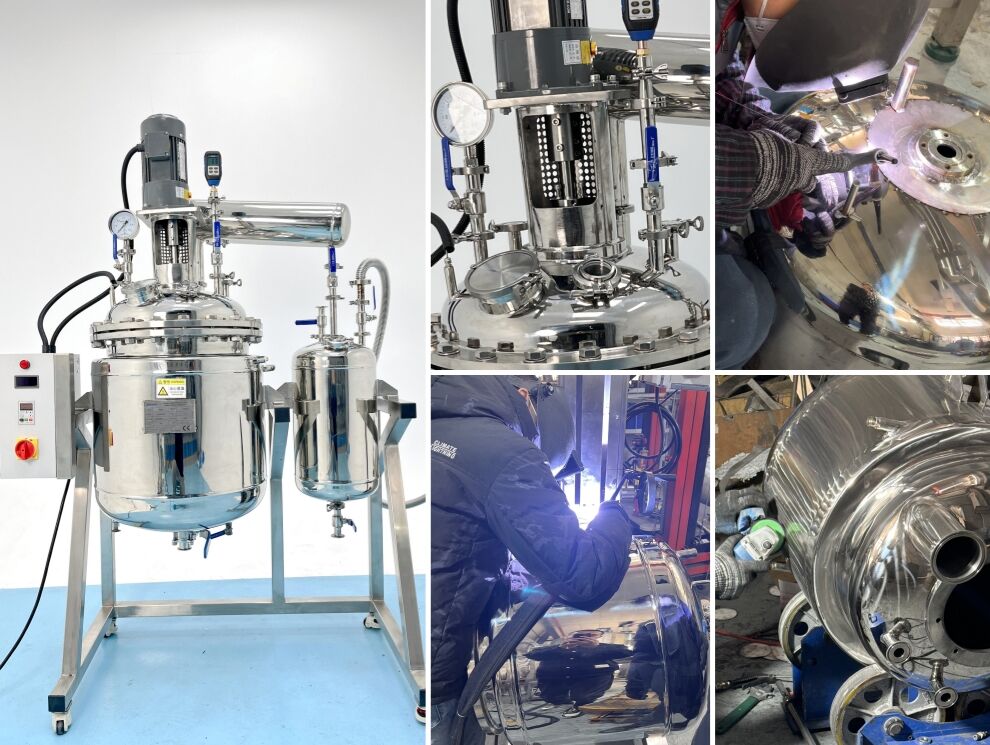

Versatile Multi-Application Design

The electric-heated extraction reactor showcases remarkable versatility through its multi-application design that accommodates diverse extraction requirements across numerous industries and processing scenarios. The reactor's modular construction allows for easy configuration changes and accessory additions, enabling users to adapt the system for different extraction methods, solvent types, and material characteristics without requiring completely new equipment investments. Interchangeable processing chambers accommodate varying batch sizes from laboratory-scale samples to full production volumes, providing scalability that grows with business needs. The system's compatibility with multiple extraction solvents, including water, organic solvents, and supercritical fluids, makes it suitable for applications ranging from essential oil extraction to pharmaceutical compound isolation and food ingredient processing. Specialized internal components, such as agitation systems, filtration assemblies, and vapor recovery units, can be customized to optimize performance for specific extraction requirements. The reactor's design accommodates both batch and continuous processing modes, providing flexibility for different production strategies and throughput requirements. Advanced process control capabilities enable users to program complex extraction sequences that may include multiple temperature phases, pressure adjustments, and timing controls, all automatically executed according to predetermined protocols. The system's robust construction materials ensure compatibility with corrosive solvents and harsh processing conditions while maintaining long-term reliability and performance consistency. Quick-change connections and tool-free assembly features minimize downtime when switching between different processing configurations or performing routine maintenance tasks. The reactor's comprehensive monitoring and control systems provide detailed process documentation that supports regulatory compliance across various industries, from pharmaceuticals requiring FDA validation to food processing operations adhering to HACCP standards. Integration capabilities allow the electric-heated extraction reactor to connect seamlessly with existing production lines, quality control systems, and facility management networks. The versatile design also accommodates future upgrades and technology enhancements, protecting equipment investments and ensuring continued compatibility with evolving processing requirements and industry standards.