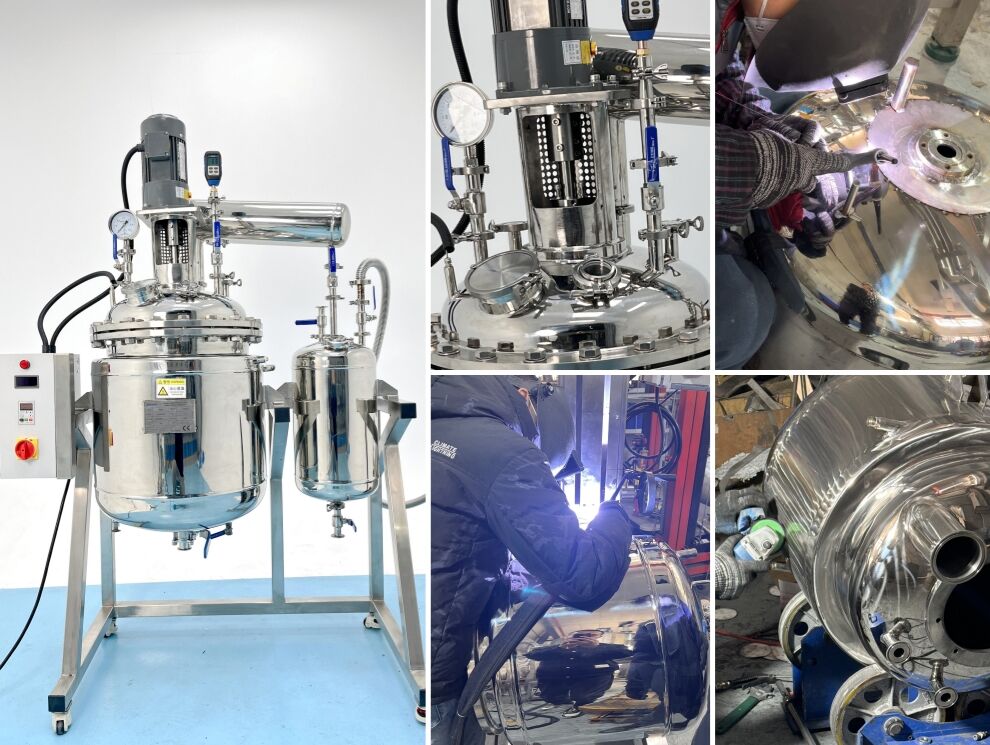

extraction reactor with condenser

The extraction reactor with condenser represents a sophisticated industrial solution designed to optimize material processing through advanced separation and recovery technologies. This integrated system combines the fundamental principles of chemical extraction with efficient condensation mechanisms to deliver superior performance in various manufacturing applications. The extraction reactor with condenser operates by creating controlled environments where target compounds are separated from raw materials using precise temperature, pressure, and solvent management. The condenser component plays a critical role by cooling and converting vaporous substances back into liquid form, enabling complete recovery of valuable materials that would otherwise be lost during processing. This dual-functionality design makes the extraction reactor with condenser an essential piece of equipment for industries requiring high-efficiency material recovery and purification processes. The technological framework incorporates state-of-the-art heat exchange systems, automated control mechanisms, and robust construction materials that ensure consistent operation under demanding industrial conditions. Modern extraction reactor with condenser units feature advanced monitoring systems that track temperature variations, pressure fluctuations, and flow rates in real-time, providing operators with comprehensive process visibility and control capabilities. The applications for this equipment span multiple industries including pharmaceuticals, chemical manufacturing, food processing, and environmental remediation. In pharmaceutical production, the extraction reactor with condenser enables precise compound isolation and purification, ensuring product quality and regulatory compliance. Chemical manufacturers utilize these systems for solvent recovery, waste minimization, and product concentration processes. The food industry benefits from gentle extraction methods that preserve nutritional content while removing unwanted components. Environmental applications include contamination cleanup, waste treatment, and resource recovery from industrial byproducts, making the extraction reactor with condenser a versatile solution for sustainable manufacturing practices.