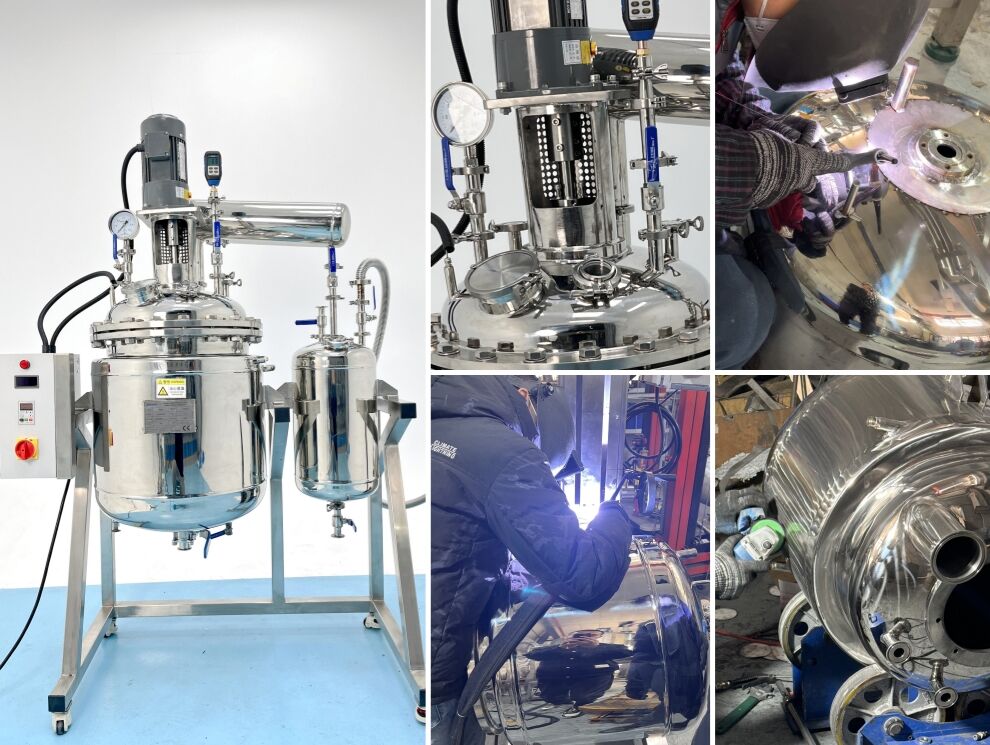

stainless steel double layer reactor

The stainless steel double layer reactor represents a cutting-edge solution for chemical processing, pharmaceutical manufacturing, and research applications. This sophisticated equipment features a unique dual-wall construction that provides exceptional temperature control and operational efficiency. The reactor consists of an inner vessel where chemical reactions occur and an outer jacket that circulates heating or cooling media, enabling precise thermal management throughout the process. The stainless steel construction ensures excellent corrosion resistance, durability, and compliance with stringent hygiene standards required in pharmaceutical and food industries. The main functions of this reactor include facilitating controlled chemical reactions, maintaining optimal temperature conditions, providing efficient mixing capabilities, and ensuring safe containment of reactive materials. The technological features encompass advanced temperature control systems, robust agitation mechanisms, pressure monitoring capabilities, and versatile port configurations for sampling and feeding. The reactor's design incorporates modern engineering principles that maximize heat transfer efficiency while minimizing energy consumption. Safety features include pressure relief valves, temperature sensors, and emergency shutdown systems that protect both operators and equipment. The stainless steel double layer reactor finds extensive applications across various industries including pharmaceuticals for drug synthesis and formulation, chemicals for polymer production and catalyst testing, biotechnology for fermentation processes, and food processing for specialized manufacturing. Research institutions utilize these reactors for developing new processes and conducting experimental studies. The versatile design accommodates different reaction types including synthesis, crystallization, distillation, and extraction processes. The reactor's scalability makes it suitable for both laboratory-scale research and pilot plant operations, providing seamless technology transfer from development to production phases.