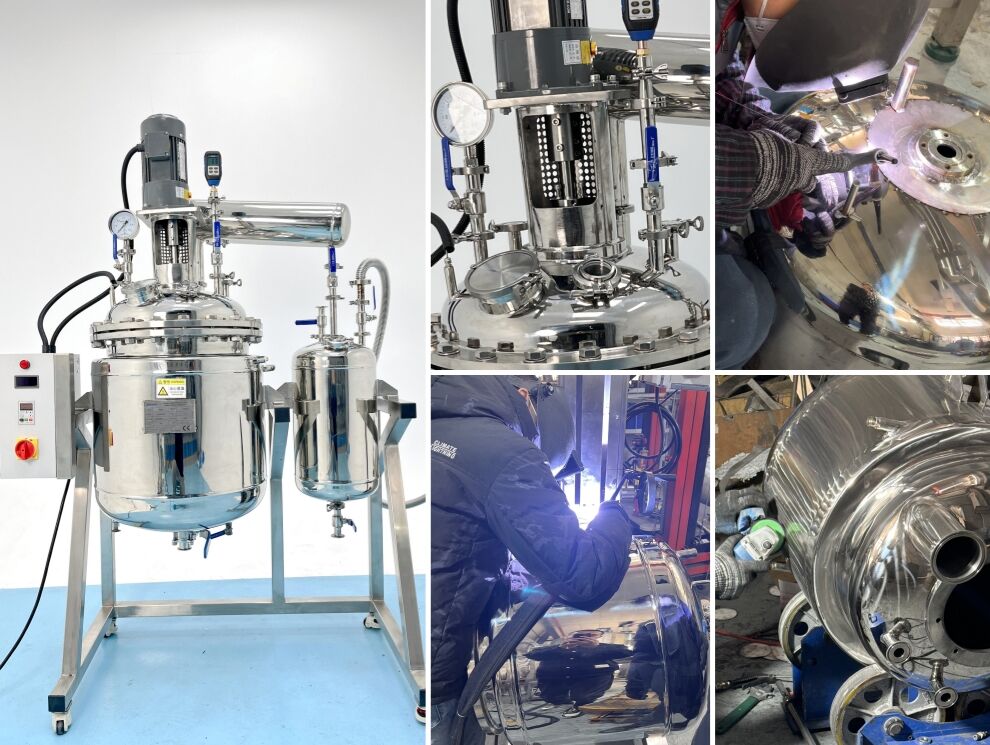

extraction reactor for essential oils

The extraction reactor for essential oils represents a sophisticated piece of industrial equipment designed specifically for the efficient recovery and purification of aromatic compounds from botanical materials. This specialized system operates as the central hub of essential oil production facilities, where raw plant materials undergo precise extraction processes to yield high-quality essential oils. The extraction reactor for essential oils incorporates advanced engineering principles to maximize yield while preserving the delicate chemical composition of natural aromatic substances. Modern extraction reactor for essential oils systems feature multiple operational modes including steam distillation, hydro-distillation, and solvent-free extraction methods. The reactor vessel typically consists of stainless steel construction with precise temperature and pressure controls, ensuring optimal extraction conditions for different botanical sources. Key technological features include automated control systems that monitor and adjust extraction parameters in real-time, ensuring consistent product quality and maximum efficiency. The extraction reactor for essential oils incorporates advanced heat exchange systems that optimize energy consumption while maintaining precise thermal control throughout the extraction cycle. Safety features are paramount, with integrated pressure relief systems, emergency shutdown protocols, and comprehensive monitoring equipment. The versatility of these systems allows for processing diverse plant materials ranging from delicate flowers to robust woody materials, each requiring specific extraction parameters. Applications span across pharmaceutical manufacturing, cosmetics production, food and beverage industries, and aromatherapy product development. The extraction reactor for essential oils enables manufacturers to maintain strict quality standards while achieving commercial-scale production volumes. Modern systems feature modular designs that allow for scalability and customization based on specific production requirements. Integration capabilities with downstream processing equipment such as separators, purification systems, and packaging lines make the extraction reactor for essential oils an essential component of comprehensive essential oil production facilities.