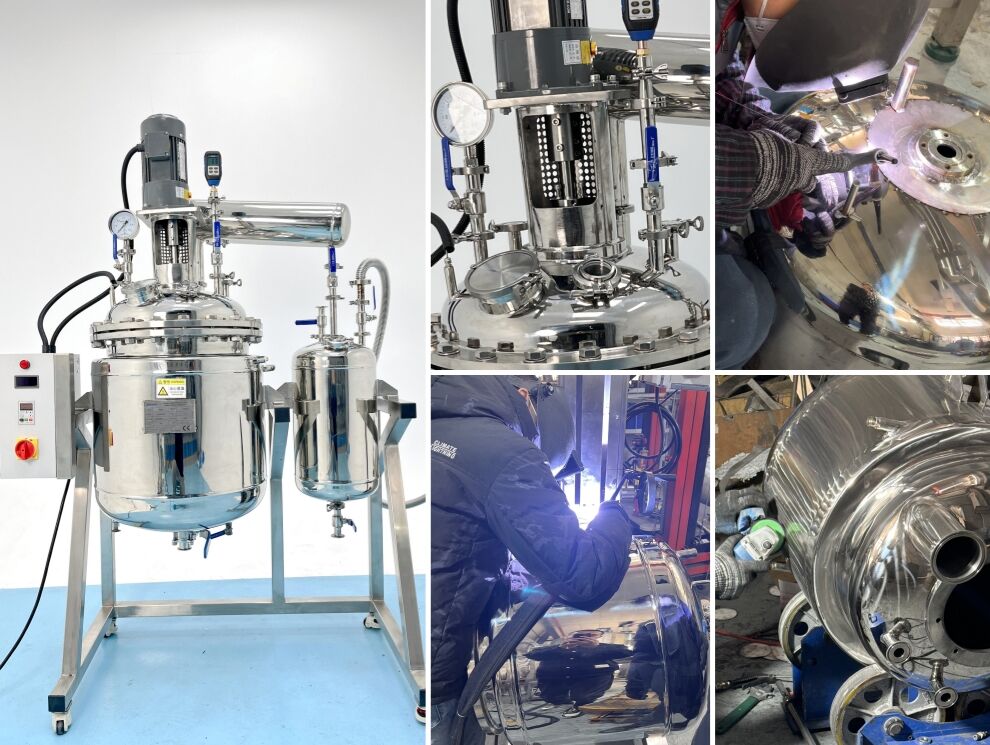

extraction reactor for solvent recovery

The extraction reactor for solvent recovery represents a sophisticated industrial solution designed to reclaim and purify solvents from various manufacturing processes. This advanced system operates on the principle of selective separation, utilizing precise temperature control, pressure management, and specialized extraction techniques to recover valuable solvents that would otherwise be discarded as waste. The extraction reactor for solvent recovery serves multiple critical functions within industrial operations, including reducing operational costs, minimizing environmental impact, and maximizing resource efficiency. The core technology incorporates multi-stage extraction processes that can handle diverse solvent types, from organic compounds to specialized chemical solutions. These systems feature robust construction materials, typically stainless steel or specialized alloys, ensuring compatibility with corrosive substances and maintaining operational integrity under demanding conditions. The extraction reactor for solvent recovery integrates sophisticated control systems that monitor temperature, pressure, flow rates, and composition parameters in real-time. Advanced filtration mechanisms remove impurities, while distillation columns separate different solvent components based on their boiling points. The technology accommodates batch and continuous processing modes, making it suitable for various production scales. Modern units incorporate energy recovery systems that capture and reuse thermal energy, significantly improving overall efficiency. Safety features include explosion-proof designs, emergency shutdown systems, and comprehensive monitoring protocols. The extraction reactor for solvent recovery finds applications across pharmaceutical manufacturing, chemical processing, paint and coating production, electronics manufacturing, and printing industries. These systems can process contaminated solvents containing suspended particles, dissolved impurities, and mixed solvent streams, delivering purified products that meet stringent quality standards for reuse in production processes.