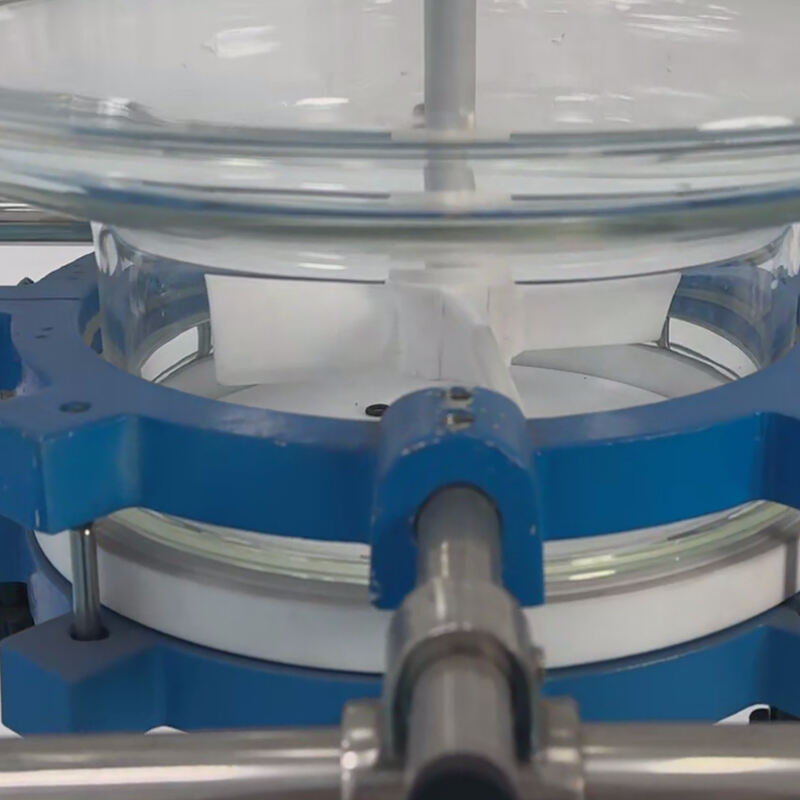

chemical crystallization reactor

The chemical crystallization reactor is a sophisticated piece of equipment designed to facilitate the process of crystal formation from liquid solutions. Its main functions include controlling the conditions necessary for the precipitation of crystals, such as temperature, pressure, and mixing rates. Technological features of this reactor encompass precision engineering, advanced control systems, and optimized heat exchange mechanisms. These features allow for the precise manipulation of the crystallization process, resulting in high-purity and well-defined crystal structures. The applications of chemical crystallization reactors are widespread, ranging from pharmaceutical production to the manufacturing of fine chemicals and materials science research.