304 316 stainless steel crystallization reactor

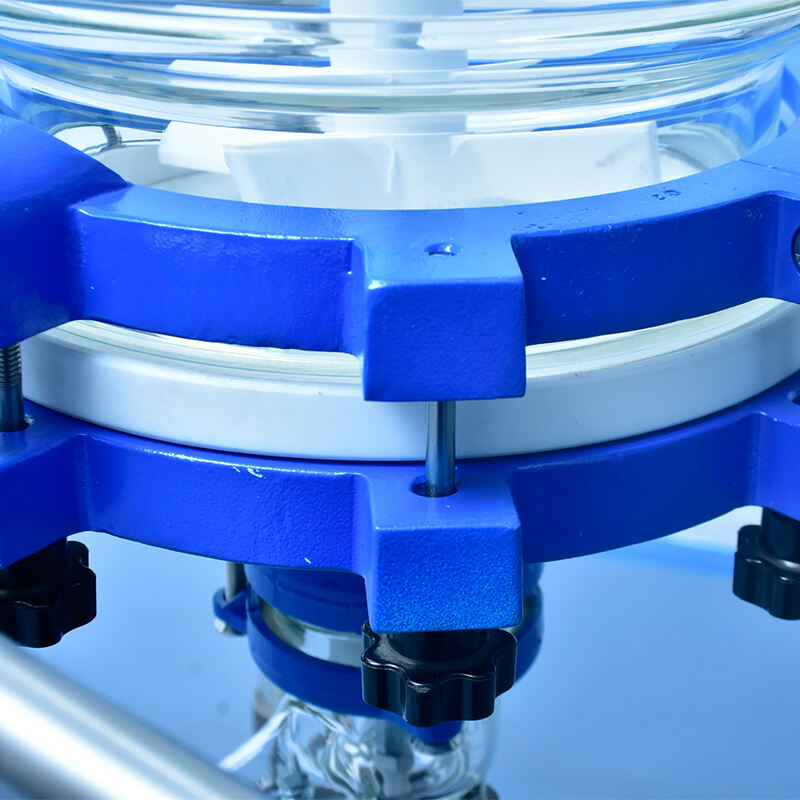

The 304 316 stainless steel crystallization reactor represents a pinnacle of industrial processing equipment, engineered to facilitate controlled crystallization processes across diverse manufacturing sectors. This sophisticated vessel combines the superior corrosion resistance of premium stainless steel alloys with advanced reactor technology to deliver exceptional performance in crystal formation applications. The reactor serves as a controlled environment where supersaturated solutions undergo systematic crystallization, enabling manufacturers to produce high-quality crystals with consistent particle size distribution and purity levels. The main functions of the 304 316 stainless steel crystallization reactor encompass temperature regulation, agitation control, and precise monitoring of crystallization parameters. These reactors excel in maintaining optimal conditions for nucleation and crystal growth, ensuring reproducible results across production batches. The technological features include advanced heating and cooling systems that provide rapid temperature adjustments, sophisticated agitation mechanisms that promote uniform mixing without damaging delicate crystals, and comprehensive monitoring systems that track critical process variables in real-time. The dual-grade stainless steel construction offers unmatched versatility, with 304 stainless steel providing excellent general corrosion resistance and 316 stainless steel delivering enhanced protection against chloride environments and aggressive chemicals. Applications span pharmaceutical manufacturing, where precise crystal formation determines drug efficacy and bioavailability, chemical processing industries requiring consistent product quality, food and beverage production for sugar and salt crystallization, and specialty chemical manufacturing. The reactor design incorporates multiple ports for sampling, instrumentation, and material addition, facilitating seamless integration into existing production lines. Advanced insulation systems minimize energy consumption while maintaining temperature stability, contributing to operational efficiency and cost reduction. The smooth interior surfaces prevent contamination and facilitate thorough cleaning between batches, meeting stringent hygiene requirements across industries.