Moleküler Destilasyon Teknolojisinin Temelleri

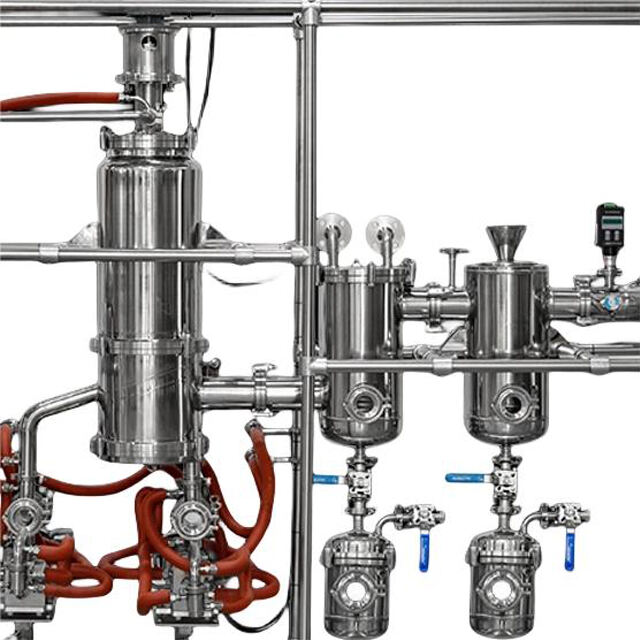

Stainless steel moleküler destilasyon sisteminin prensibi

The Paslanmaz Çelik Moleküler Damıtma Sistemi moleküler destilasyonda yaygın olarak kullanılır, kortaj yolu buharlaşmayı kullanarak buharın seyahat mesafesini minimize eder ve ısıya duyarlı maddeleri korur. Bu sistem, kaynama noktalarını düşürmek için vakum koşullarını koruyarak hassas bileşenlerin bütünlüğünü sağlar.

Ana Bileşenler: Vakum Pompa ve Buharlaştırıcılar

Böyle istenmeyen reaksiyonları engellemek için (ve ürünün lezzetine uygun olmak için), moleküler distilasyon sürecinde vakum pompa kullanımı kritik öneme sahiptir, çünkü bu pompa süreç için gereken düşük basıyı sağlar. Bu azaltılmış basınçta, çözücüyun kaynama noktası düşer ve bu da daha hızlı buharlaşma ve bileşenlerin daha iyi ayrılmasıyla sonuçlanır. Önemli bir gereksinim olarak aynı zamanda kısa yolu distilasyonu için tasarlanmış yüksek kapasiteli buharlaştırıcılar bulunmaktadır. Bu cihazlar, bileşenlerin yüksek sıcaklıklara maruz kalma sürelerini en aza indirerek distillat toplama verimliliğini ve saflığını artırır ve böylece termal olarak hassas maddeleri korur. İnce film buharlaştırıcıları bu türden bir cihazdır ve çeşitli viskoziteleri işleme yetenekleri ve moleküler distilasyondaki uygulamalarında etkinlikleri nedeniyle tanınır. Hepsi de kendi özel işlevlerine sahip olup, operasyonların mümkün olduğu şekilde ve ürün türüne göre işleme katkıda bulunur ve en iyi işleme için özelleştirilmiş bir reçete oluşturur.

Geleneksel Ayırma Yöntemleriyle Karşılaştırma

Moleküler distilasyon, termal olarak duyarlı moleküller için daha yüksek ayırma verimliliği nedeniyle geleneksel ayrıştırma süreçleri olan distilasyon ve ekstraksiyonlardan farklıdır. Moleküler distilasyon, yüksek vakum altında ve son derece düşük işleyiş basıncında, makinenin işleyiş basıncını azaltır ve sıvı malzeme seyahat mesafesini kısaltır ki bu da yukarıdaki etkileri ortadan kaldırır. Bu, hafif koşullar altında kesinlikle ayrılmalıdır ki bu da daha yüksek safliklere ve verimlere yol açmaktadır. Yıllar boyunca ortaya çıkan bir dizi sanayi durumu raporu, geleneksel teknolojiyi kullanarak: mop ve paleye yan yana moleküler distilasyon kurulumları ile pürifikasyonun önemli ölçüde arttığını ve üretim oranını artırdığını göstermektedir. Bu verimlilik, distilasyon sonrası temizleme prosedürlerine olan gereksinimin azalmasıyla daha da desteklenmiştir, moleküler distilasyonu ilaç ve gıda sanayileri gibi önceden görülmemiş bir hassasiyet düzeyi gerektiren sanayilerde en ileri teknolojilerden biri olarak doğrulamaktadır.

Sanayi Distilasyonunda Paslanmaz Demirin Avantajları

Saldırgan Ortamlardaki Korozyon Dayanımı

Korozyon Dayanıklı Paslanmaz demir korozyon dayanıklısıdır ve bu da onun agresif çözücüler ve kimyasallarla uğraşmak zorunda olan distilasyon süreçlerinde yaygın olarak kullanıldığındaki nedenidir. Bu özellik, sadece makine ömrünü uzatır, aynı zamanda bakım maliyetlerini de önemli ölçüde azaltır. Bazı paslanmaz çelik sınıfları, kimya işlemede kullanılan ısı değiştiriciler için diğerlerinden daha iyi performans gösterir. Tüm ekipmanlar, çürümeye veya korozeye uğramamasını ve sert sanayi distilasyon ortamları için uygun hale getirmesini sağlamak için 304 veya 316 paslanmaz çeliğinden yapılmıştır.

Yüksek Basınçlı İşlemler Altında Yapısal Bütünlük

Rozet çeliğinin dayanımı, yüksek basınçlı destilasyon uygulamalarında önemli bir avantajdır. Güçlü mekanik özelliklerinden dolayı kullanımda deformasyona uğramaz ve sistemin etkinliğini, güvenilirliğini ve işlemesini korumakta temel bir rol oynar. Üretim standartları ve sertifikalar, yüksek basınç altında çalışan ekipmanlarda kullanılan malzemenin dayanımının önemine dikkat çekerek performansın güvenilirliğini ve işlemin güvenliğini sağlar. Rozet çeliğinin uzun ömürlülüğü, yoğun kullanım ve yüksek akış gereksinimlerini karşılayabileceğini gösterir ki, bu da herhangi bir endüstriyel destilasyon kurulumunda idealdir.

Duyarlı Uygulamalar İçin Sağlıklı Özellikler

Edelinox çeliğinin hijyenik özellikleri, bu özelliklere ihtiyaç duyan uygulamalar için idealdir. Yüzeyleri farmasötik ve gıda endüstrilerinde gereklidir gibi kolayca steryle edilebilir. Edelinox çeliği herhangi bir bakteriyi tutmaz ki bu da gıdanın taşmasıyla ilgili hastalıkları önlemeye yardımcı olabilir. Kirlilik istatistikleri, hijyen duyarlı ortamlarda tercih edilen malzeme olarak edelinox çelizi göstermektedir. Bu materyal tüm düzenleyici gereksinimlerle uyumlu ve talep edilen endüstriyel uygulamalarda hassas ürünlerin bütünlüğünü sağlar.

Verimliliği Artıran Tasarım Özellikleri

Daha Hızlı İşlem için Termal Optimizasyon

Isı yönetimi, moleküler distilasyon sürecinin etkili çalışması için ana faktörlerden biridir. Ultra-etkin termal sistemler, daha hızlı işleme ve azaltılmış enerji tüketimi için daha iyi ısı aktarımı sağlar. Böyle bir ortamda, akış ve sıcaklık dağılımı için optimizasyondaki kritik rolü oynayan ısı değiştiriciler, daha etkili bir sıcaklık yönetimi izin verir. Bu, hassas maddelerin temizleme süreçleri için özellikle faydalıdır çünkü bu süreçler tam olarak belirlenmiş sıcaklıkları gerektirir. Endüstri araştırmalarından elde edilen performans verileri, artırılmış verimlilik ve kaynak tasarrufuyla birlikte bu ileri düzeydeki termal çözümlerle sistemlerde işleme sürelerinde önemli azalmalar olduğunu göstermiştir.

Azaltılmış Bakım Gereksinimleri

Sanayi distilasyon sistemleri için, düşük bakımdan verimli bir süreklilik operasyonuna anahtar. Benzersiz tasarım kavramları, daha az bakım gerektiren ve kapattıktan sonra minimum sürede yeniden çalışabilen sistemlere yol açmıştır. Bu tasarımlarda modüler bileşenlerin kullanımı hızlı değişimleri ve tamirleri destekleyerek kapalı kalma süresini ve maliyeti azaltır. Genel bir kural olarak, bir sistemin tasarımı ile bakım sıklığı arasında ters orantılılık olduğu da söylenebilir; daha basit ve iyi entegre edilmiş tasarım, destek açısından zaman içinde daha iyi performans gösterir, bu da onu daha dayanıklı ve güvenilir hale getirir.

Otomasyon Entegrasyon Kapasiteleri

Otomasyon teknolojisinin destilasyon birimlerinin performansı üzerindeki etkisi, destilasyon sistemlerinin işleyiş davranışını dönüştürüyor. Otomasyon karmaşıklığı azaltır ve her seferinde kaliteli ürünler sağlayarak kapasiteyi artırır. Gelişmiş izleme cihazları, erken müdahaleyi destekleyen ve insan hatasının olasılığını azaltan anlık veri görünürlüğü sağlar. Bu süreç yalnızca daha verimli bir işlemdir, aynı zamanda çevresel olarak sürdürülebilir sürekli operasyonların endüstri ihtiyaçlarını karşılayabilir. Endüstri kullanıcısı anketleri, verimlilik artışında eşsiz olan otomatik sistemlerin uygulama süreçlerinde kullanılmasına yönelik artan bir talep göstermiştir; bu da sonuçların kalitesini korurken üretkenliği artırmada olanak tanıdığı için otomasyon teknolojisinin maliyetlerini gidermek için esastır.

Seçenekli Teknolojilerle Karşılaştırmalı Analiz

Rotary Destilatörler Karşılaştırması: Etkinlik Ölçüleri

Moleküler distilasyon sistemleri, yüksek safliklu çıkarımlar ve izolasyonlar yapmak için geleneksel bir döner buharlaştırıcıya göre üstün sonuçlar sunar. Termal özellikler şüphesiz termal bozunumun azaltılması nedeniyle hassas bileşikleri korur ve bu da bu üstünlüğün ana sebebidir. Verimlilik miktarları karşılaştırıldığında, moleküler sistemler ürün verim oranları ve enerji tüketimi açısından açık bir şekilde farklılaşır. Bu hususlar, saflik ve performans ile ilgilenen sektörler için özellikle uygun olduklarını gösterir. Karşılaştırma testinde moleküler distilasyon sisteminin kalitesi hala üstündür, bu da zaten bilinen yöntemle aynı şekilde yüksek kaliteli bir ürün elde etmeyi sağlar.

Düşey Film Evaporatörleri Üzerindeki Avantajlar

Moleküler distilasyon, özellikle ayrım alanında düşey film buharlaştırıcılarını geçer. Ince film süreçlerinden farklı olarak, moleküler birimler belirli bileşenleri daha etkin şekilde ayırabildikleri için, hassasiyet önemli olan belirli kimyasal süreçlerde tercih edilirler. Ayrıca, daha düşük enerji maliyeti olduğundan, yıllar boyunca işletme masrafları daha azdır. Endüstri standartları, moleküler distilasyon ile düşey film buharlaştırıcılarına göre daha fazla değerli bileşeni geri kazanacağınızı gösterir. Bu, üretkenlik ve verimlilikle daha çok ilgilenen ticari yapıların moleküler distilasyonu çekici bir seçen bulmasının nedenleridir.

Silme Film Distilasyonuna Göre Performans

Kurulmuş film destilasyonu faydalı olsa da, moleküler destilasyon bu tür hassas malzemelerle ilgili olarak genellikle daha iyi bir iş yapar. Moleküler destilasyonun performansları sunulmaktadır ve burada genel akış miktarının artırıldığı gibi ürün kalitesindeki ortalama termal stresin de azaldığı gösterilmektedir. Bu, bitiş ürünlerinin sadece daha hızlı yapıldıkları değil aynı zamanda istenen özelliklerini koruduklarını da garanti eder. Moleküler destilasyon bazen verimi maksimize etme ve saflik derecesi açısından en iyi seçenek olarak adlandırılır. Dolayısıyla, hassasiyeti ve hızı ön planda tutan uygulamalar için kurulmuş film destilasyonundan daha fazla avantaj sunan moleküler destilasyonun yenilikçi faydaları bulunmaktadır.

Sanayi Uygulamaları ve Verimlilik Kazançları

İlaç ve Biyofarmaseytik Üretim

Moleküler distilasyon, tüketicinin sağlığına yönelik tutarlı kalite ve saflik gerektiren ilaç süreçlerinin geleceğini dönüştürüyor. Daha fazla bilgi. Sıcıl hasar verebilecek süreçlerle karşılaştırıldığında, moleküler distilasyon, yüksek vakumda gerçekleşen bir ayırma sürecidir ve ayrılacak bileşenler arasındaki buhar basıncı farkı nedeniyle moleküler ayrımın seçiciliğine yol açar, böylece termal duyarlı bileşenlere zarar vermeden işe yarar. Yeni istatistiksel bulgular, bu sistemlerin biyofarmase kominasyon süreçlerinde uygulanmasında keskin bir artışa işaret ediyor. Bu yükseliş, en sert saflik düzenlemelerine uyabilme kapasiteleri ve ilaçların tüketiciler için güvenli ve etkili olmalarını sağlamak amacıyla verimliliği artırmaya yönelik yeteneklerinden kaynaklanmaktadır.

Essans Yağı Konsantrasyon Süreçleri

Temel Yağmur üretiminde, moleküler destilasyon artık duyarlı aromatik özelliklerin korunmasına yönelik verimli bir şekilde yağları konsantre etmede ayrılmaz bir parçadır. Geleneksel destilasyon teknikleri kullanıldığında, değerli bileşenler (terpenler ve flavonoidler) kaybedilmektedir. Ancak bu bileşenler bağlamında, moleküler destilasyon kullanarak onları korumakta önemli faydalar bulunmaktadır. Güncel pazar araştırmaları, tüketicilerin bu teknolojiyle işlenen ürünler tercih ettiği ortaya koymuştur, bunun nedeni sensörsel özellikler açısından kalitenin daha iyi olmasıdır. Bu sonuçlar, moleküler destilasyonun, aromatik ve lezzet kullanımına yönelik yüksek kaliteli temel yağlar hazırlamada etkili bir araç sunduğunu göstermektedir.

Atık Su Tedariği ve Kaynak Geri Kazanımı

Moleküler distilasyon, özellikle solventlerin geri kazanımı konusundaki 'dairesel ekonomi' bağlamında atık su tedavisinde yüksek kaliteli bir yaklaşımdır. Bu süreç etkin şekilde kirlilikleri kaldırır ve birden fazla endüstride sürdürülebilirliği ilerletir. Çalışmalar, bu teknikleri destekleyen bir sistemin geri kazanım oranlarının elde edilmesini eniyileyeceğini ve kullanılmayan ve atılsın diye bırakılan malzemelerin kullanımını eniyileyeceğini göstermektedir. Üretken ayırma prosedürleri sayesinde bu moleküler distilasyon teknolojisi sadece atıkları azaltmakla kalmaz, aynı zamanda çevreye dost bir üretim yaklaşımını mümkün kılar (ayrıca, çevresel koruma yasası uzakta olmadığı için bu moleküler distilasyon uygulaması kesinlikle giderek daha fazla talep görmeye başlamıştır).

Distilasyon Teknolojisi ile İlgili Gelecek Eğilimleri

Akıllı İzleme ve Kontrol Gelişmeleri

Bu AI ve makine öğrenimi ile geliştirilen ilerlemeler entegre edilince, destilasyon teknolojisinin geleceği büyük bir atılım yaşayacak. Bu, destilasyon süreçlerinin zeki izlenmesine ve gerçek zamanlı kontrollerine olanak tanıyarak performansın önemli ölçüde artırılmasına yol açacaktır. Tahminsel bakım, yapay zekâ destekli sistemler, iş sürekliliğini azaltmaya ve genel sistem güvenliğini artırmaya yardımcı olur. Tahminler, otomasyon ve üretkenlik artışı talebinin yükseldiği akıllı destilasyon sistemleri için büyük bir piyasa büyümesi işaret etmektedir. Bu eğilim, manzarayı yeniden şekillendirecek - işletmeler rekabet etmek istiyorsa bu yenilikleri benimsemelidir.

Enerji Kurtarma Sistemleri Entegrasyonu

Enerji geri kazanma süreçlerindeki kolaylık ve ilerlemeler önümüzde bekleniyor ve destilasyon süreçlerinin sürdürülebilirliğini artırmak için işletme maliyetlerini önemli ölçüde azaltacaklar. Enerji geri kazanma sistemlerini entegre ederek, işlemlerin verimliliği yalnızca artacak, aynı zamanda acil çevresel zorlukları tanıyarak küresel sürdürülebilirlik programlarına uygun hale gelecektir. İstatistiksel analiz, endüstriyel uygulamalarda maliyet azaltma potansiyellerinin büyük olduğunu vurguluyor. Endüstrinin daha sürdürülebilir çözümlere doğru ilerlediği medida, enerji geri kazanımı destilasyon süreçlerine entegrasyonu hem ekonomik hem de sürdürülebilirlik açısından giderek daha da önem kazanacaktır.

Malzeme Bilimi İnovasyonları

Malzeme biliminde şu anda distilasyonu bir teknoloji olarak düşündüğümüzü değiştirebilecek olanaklar sunan heyecan verici gelişmeler yaşanıyor. Distilasyon ekipmanları için yeni alaşım ve kaplama malzemeleri, aşınmayı ve korozyonu en aza indirerek hem performansını hem de ömrünü artırmaya olanak tanır. Bu özellikle yüksek kalite gerektiren distilasyon uygulamaları için son derece kritiktir. Eğitmenler, distilasyonun sanayi gereksinimlerini karşılamak için malzeme biliminin geliştirmesinin en üst düzeyde olduğunu vurguluyor. Bu ilerlemeler, bugünün daha zorlayıcı sanayi ortamlarında distilasyon ekipmanlarının hayatta kalması ve optimizasyonu açısından temel importance taşır.

SSS

Stainless Steel Moleküler Distilasyon Sistemi kullanmanın ana avantajı nedir?

Stainless Steel Moleküler Distilasyon Sistemi kullanmanın ana avantajı, agresif ortamlarda uzun ömür sağlanması ve bakım maliyetlerini azaltması için korozyon direncidir.

Moleküler distilasyon, geleneksel distilasyon yöntemlerinden nasıl farklıdır?

Moleküler distilasyon, kaynama noktalarını düşürmek için vakum koşullarının kullanılmasıyla geleneksel yöntemlerden farklılaşır ve ısıya duyarlı bileşikler için ayrıştırma verimliliğini artırır.

Moleküler distilasyon, biyofarmaseytik üretim için neden özel olarak faydalıdır?

Moleküler distilasyon, hassas bileşiklerin bütünlüğünü koruyarak farmaseytik ürünlerin yüksek saf mooie ve etkinliğini sağladığı için biyofarmaseytik üretimi için faydalıdır.

Otomasyon, modern distilasyon sistemlerinde hangi rol oynar?

Modern distilasyon sistemlerinde otomasyon, verimliliği artırır, ürün kalitesini sürekli olarak sağlar ve gelişmiş izleme ve anlık ayarlara dayalı olarak insan hatasını minimuma indirger.

Distilasyon endüstrisini şekillendirecek gelecekteki eğilimler nelerdir?

Distilasyon endüstrisindeki gelecek eğilimler, daha akıllı izleme için AI'nin entegrasyonu, çevreye daha dost canlık için enerji kurtarma sistemleri ve artırılmış dayanıklılık için malzeme bilimlerindeki yenilikler içerir.

İçindekiler

- Moleküler Destilasyon Teknolojisinin Temelleri

- Sanayi Distilasyonunda Paslanmaz Demirin Avantajları

- Verimliliği Artıran Tasarım Özellikleri

- Seçenekli Teknolojilerle Karşılaştırmalı Analiz

- Sanayi Uygulamaları ve Verimlilik Kazançları

- Distilasyon Teknolojisi ile İlgili Gelecek Eğilimleri

-

SSS

- Stainless Steel Moleküler Distilasyon Sistemi kullanmanın ana avantajı nedir?

- Moleküler distilasyon, geleneksel distilasyon yöntemlerinden nasıl farklıdır?

- Moleküler distilasyon, biyofarmaseytik üretim için neden özel olarak faydalıdır?

- Otomasyon, modern distilasyon sistemlerinde hangi rol oynar?

- Distilasyon endüstrisini şekillendirecek gelecekteki eğilimler nelerdir?