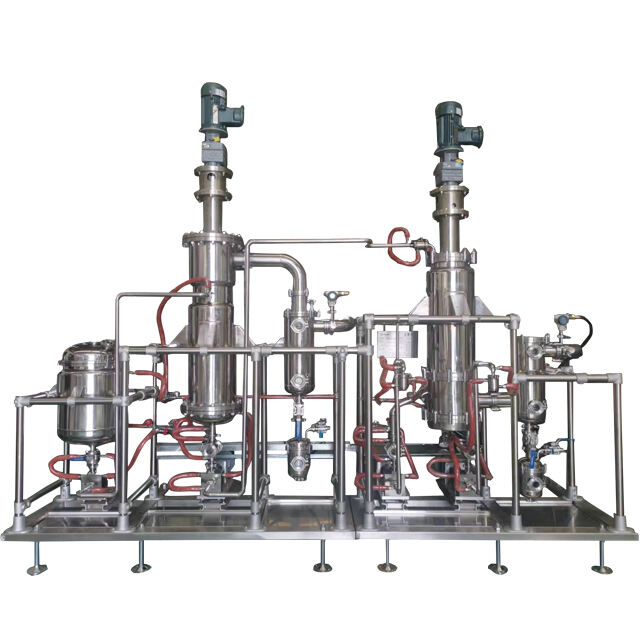

nonjacket glass reactor

The nonjacket glass reactor is a state-of-the-art piece of laboratory equipment designed for a variety of chemical reactions that require accurate temperature control and visibility. This reactor is primarily used for processes like synthesis, digestion, and process development. Key functions include the containment of reactions within a controlled environment, enabling scientists to observe reactions directly due to the transparent glass construction. Technological features of the nonjacket glass reactor include a high-quality borosilicate glass vessel that can withstand high temperatures and chemical corrosion, a robust PTFE stirring system to ensure uniform mixing, and a variety of available accessories such as condensers and collectors. Its applications span across pharmaceuticals, biotechnology, and material science, making it an indispensable tool in research and development.