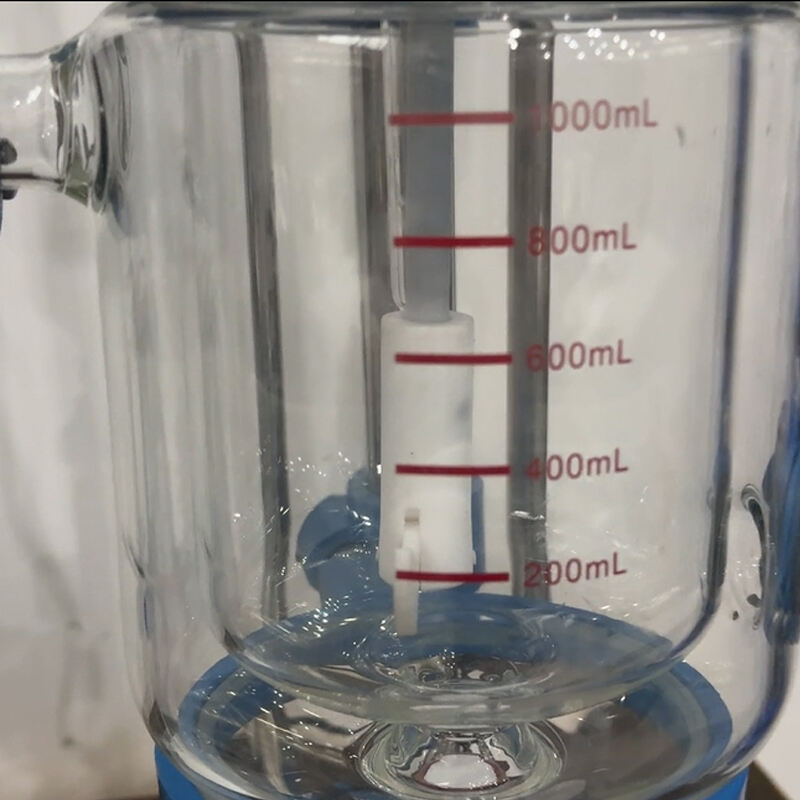

single layer glass reactor

The single layer glass reactor is a state-of-the-art piece of equipment designed for a variety of chemical processes. Its main functions include synthesis, digestion, and concentration of substances under controlled conditions. Technological features of this reactor include a high-quality, borosilicate glass construction that ensures excellent chemical resistance and durability. The single layer design promotes efficient heat transfer, making it ideal for temperature-sensitive reactions. This reactor is also equipped with a robust stirring system and precise temperature control, ensuring uniform mixing and consistent results. Its applications span across industries such as pharmaceuticals, biotechnology, and material science, where it is used for research and development as well as small-scale production.