mixing reactor

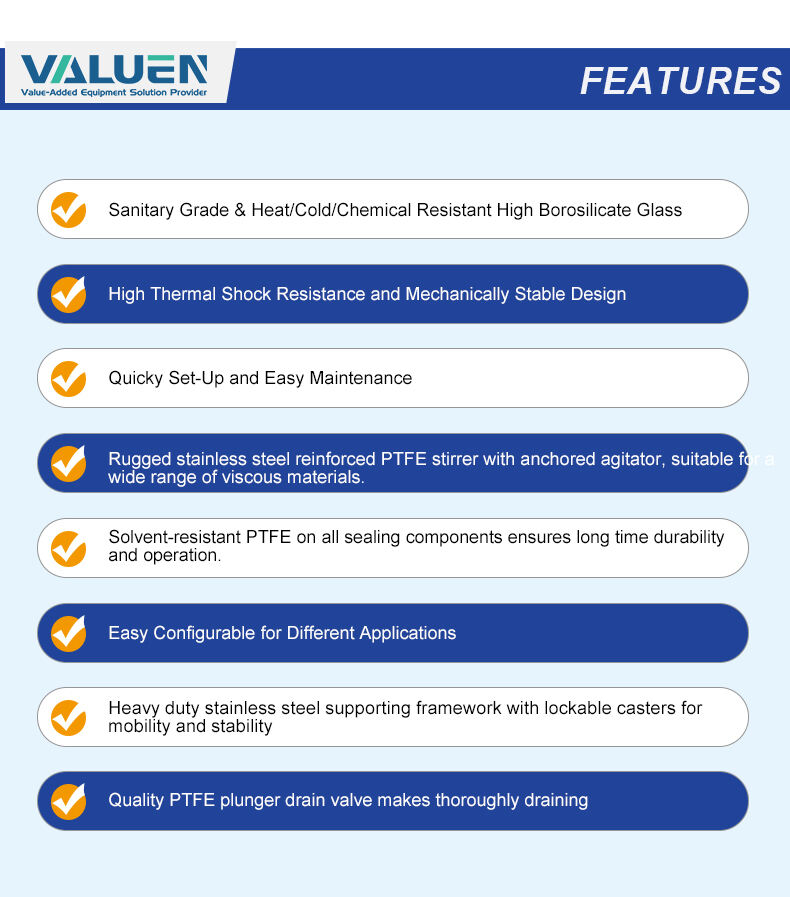

The mixing reactor is a precision-engineered piece of equipment designed to facilitate the thorough blending of substances in various industries. Its main functions include the mixing, blending, and reacting of liquids, gases, and sometimes solids, to create a uniform product that meets stringent quality standards. Technological features of the mixing reactor include a robust design that can withstand harsh process conditions, variable speed agitators for optimal mixing efficiency, and advanced control systems that ensure precise process parameters. These features make the mixing reactor suitable for a wide range of applications, from pharmaceutical production to chemical processing and food manufacturing.