jacketed glass reactors vessel

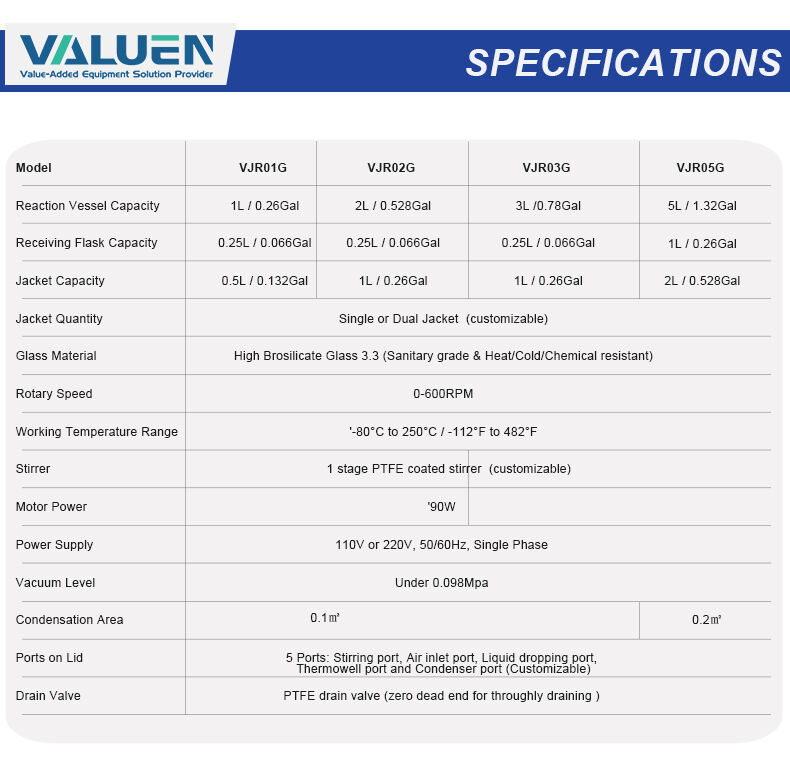

The jacketed glass reactors vessel is a state-of-the-art piece of laboratory equipment designed for a variety of chemical reactions that require controlled temperature conditions. This vessel features a glass container enclosed within a jacket, which allows for the circulation of a temperature-controlled fluid. Its main functions include mixing, reaction, and process development in fields such as pharmaceuticals, biotechnology, and material sciences. Technological features include a robust design that can withstand high pressures and temperatures, aseptic processing capabilities, and a range of sizes to accommodate different batch volumes. Applications span from research and development to pilot-scale production, offering versatility and precision for scientific and industrial processes.