stainless steel reactors

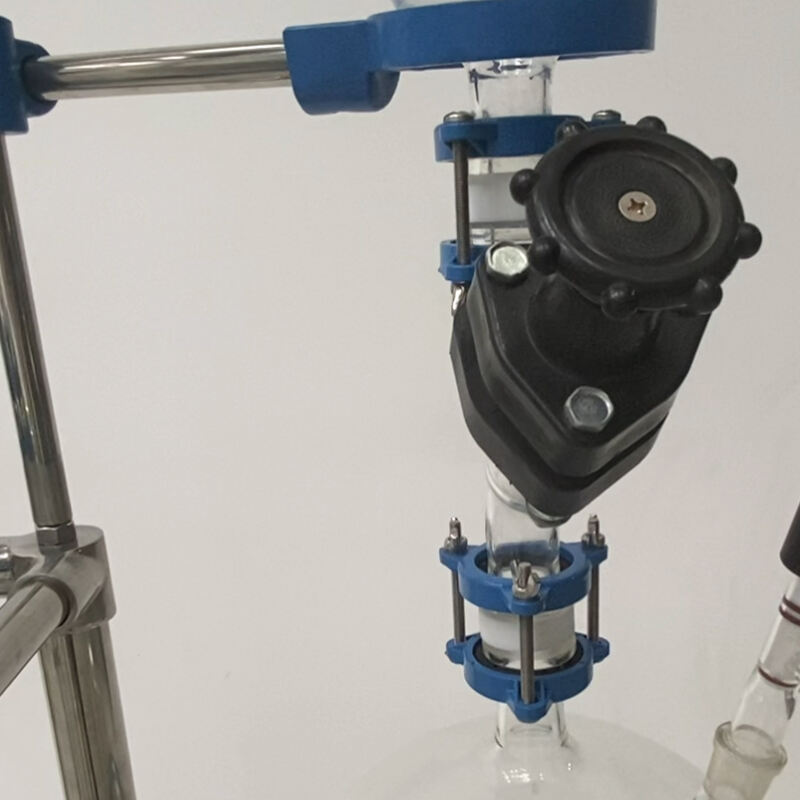

Stainless steel reactors are precision-engineered systems designed to facilitate a variety of chemical reactions and processes under controlled conditions. These reactors are characterized by their robust construction, which utilizes high-grade stainless steel materials to ensure durability and resistance to corrosion. The main functions of stainless steel reactors include mixing, blending, heating, cooling, and containment of reactive substances. Technological features such as jacketed designs for temperature control, automated control systems for process regulation, and the ability to withstand high pressures make them indispensable in numerous industries. Applications span across pharmaceuticals, fine chemicals, food processing, and bioengineering, where the integrity of the process is paramount.