oil circulating heater

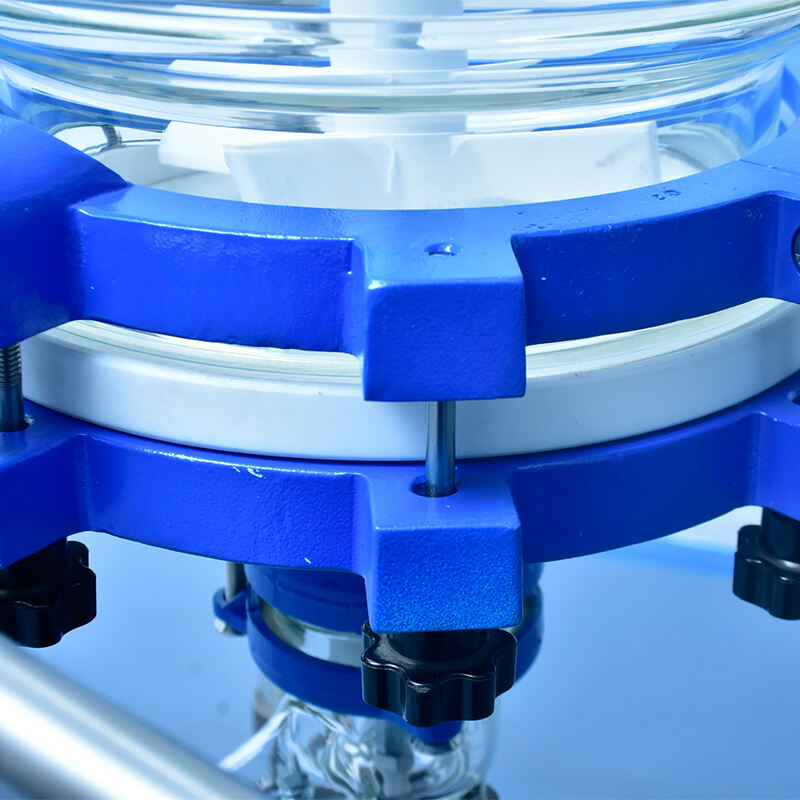

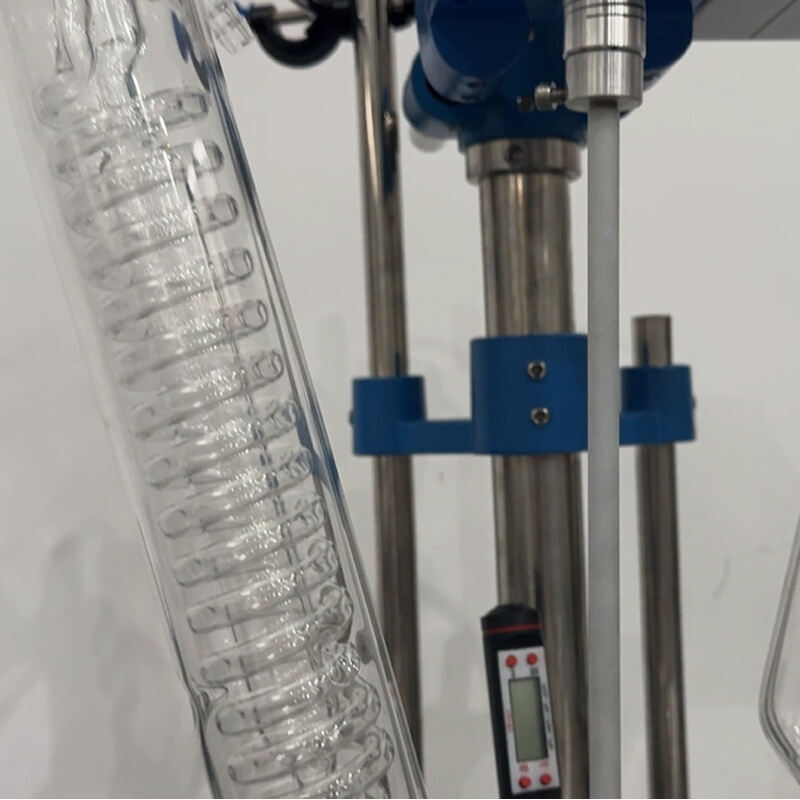

The oil circulating heater is a sophisticated piece of equipment designed to efficiently heat fluids in industrial applications. Its main function is to maintain a consistent temperature of oils and other heat transfer fluids, ensuring optimal performance of machinery and processes. Technological features of the oil circulating heater include a robust design with high-grade heating elements, a circulation pump for even distribution of heat, and advanced temperature control systems. These features allow for precise temperature regulation and safe operation. Applications of the oil circulating heater span across various industries, such as automotive, pharmaceutical, and food processing, where temperature control is critical.