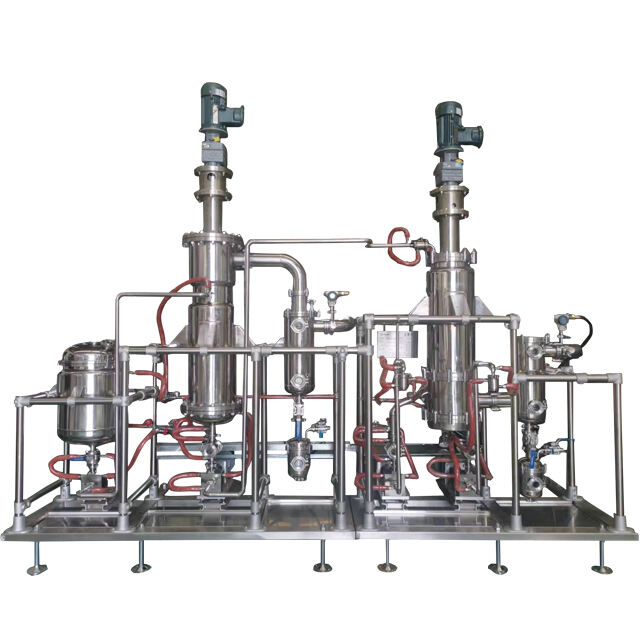

glass molecular distillation equipment

The glass molecular distillation equipment is a sophisticated piece of technology designed for the efficient and precise separation of liquids at a molecular level. Mainly used in the chemical, pharmaceutical, and food industries, this equipment utilizes the principles of short-path evaporation. Its primary functions include the removal of volatile contaminants, concentration of heat-sensitive materials, and purification of high-value compounds. Technological features such as a heated glass spiral and a rotating wiper system ensure uniform heating and prevent liquid from adhering to the glass surface, maintaining the integrity and quality of the product. The applications of this equipment range from the production of essential oils to the purification of pharmaceutical actives, showcasing its versatility and necessity in various industries.