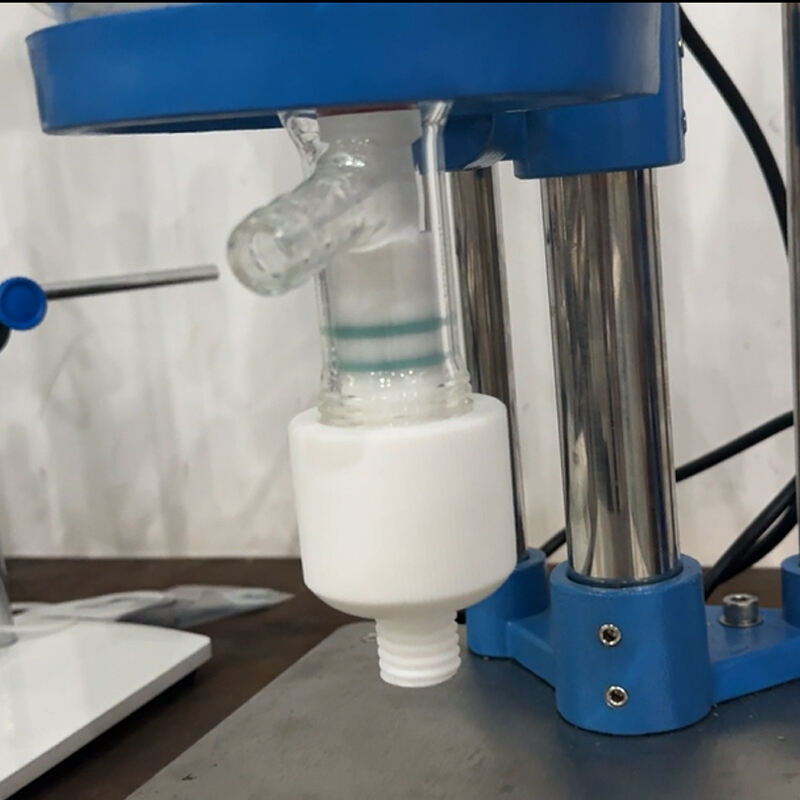

glass fractional distillation equipment

The glass fractional distillation equipment is a sophisticated piece of laboratory apparatus designed for the precise separation of liquid mixtures based on differences in boiling points. Its main functions include the distillation of complex mixtures, enabling scientists to isolate individual components with high purity. Technological features of this equipment include a durable glass construction that provides excellent chemical resistance and visibility, a heated mantle for even and accurate temperature control, a fractionating column that enhances separation efficiency, and a receiver system to collect the distillate. Applications span across various industries, including pharmaceuticals, petrochemicals, and academic research, where the ability to purify substances is critical.