Introduction to Wiped Film Molecular Distillation

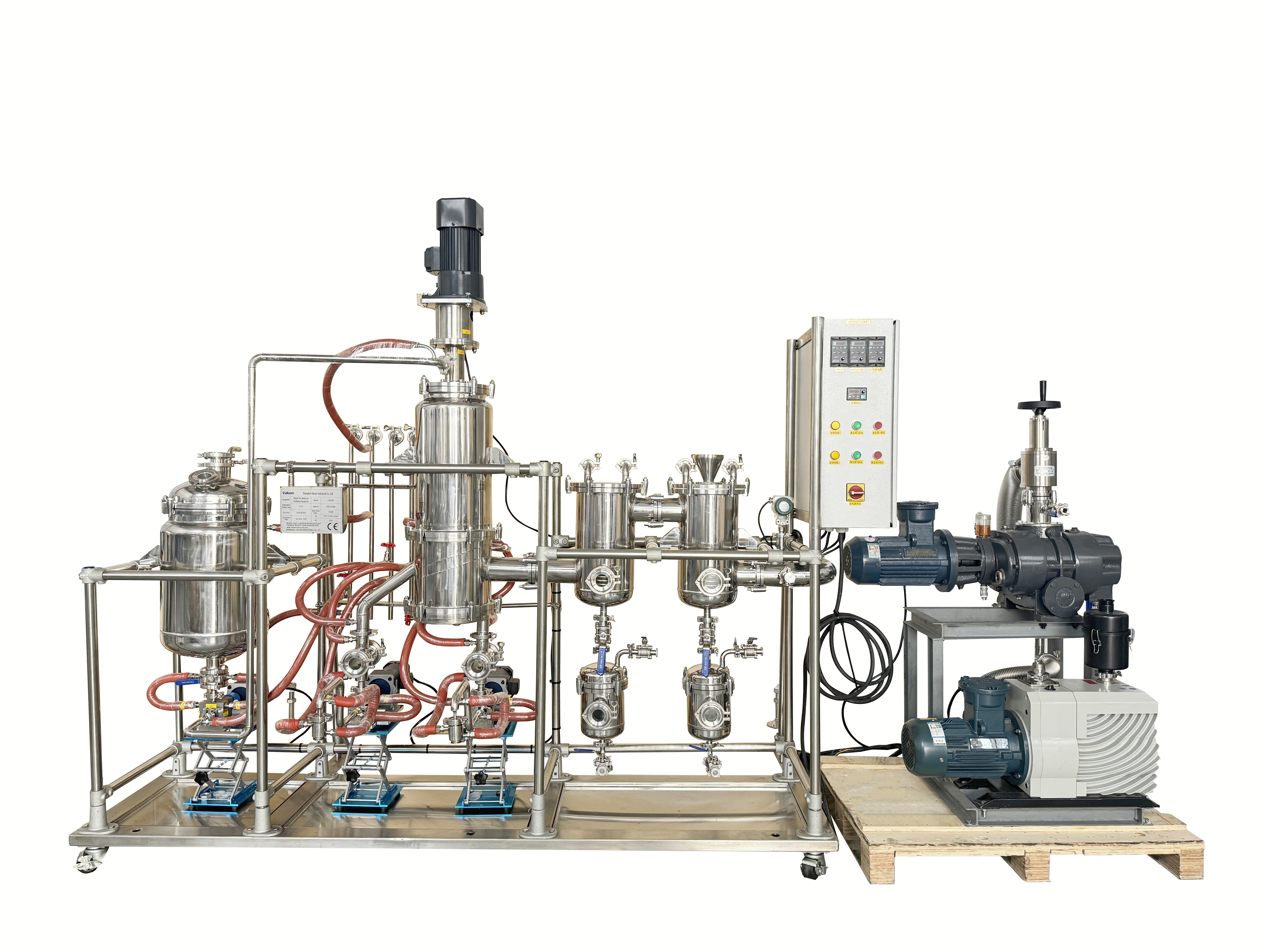

Wiped film molecular distillation stands out as an advanced method for purifying and concentrating different substances. The process works differently from conventional techniques because it spreads a very thin layer of liquid over a warm surface while continuously wiping it away. This creates fast evaporation and condensation cycles that work much better than standard approaches. Many chemical and pharmaceutical companies find this technique particularly useful when handling tricky mixtures where maintaining product quality matters most. The result? Cleaner end products without compromising on yield or speed of production.

The technique works really well when dealing with materials that break down easily under heat. Industries across the board have started adopting this approach, especially in making medicines, processing foods, and handling expensive chemical compounds. After all, nobody wants their end product compromised during manufacturing. What sets this apart from other methods is how it minimizes the chance of things breaking down due to excessive heat exposure. For companies trying to improve what they offer on the market, wiped film molecular distillation has become something of a game changer in recent years.

Getting to grips with how wiped film tech works can really transform business operations. Companies that understand these principles often see improvements across multiple areas at once - better products come out of the process, production runs become smoother, and energy bills tend to drop as well. When manufacturers know what's going on under the hood, they're able to pick the right separation methods for their particular needs. This means meeting all those regulatory requirements without breaking the bank on unnecessary expenses. For anyone serious about making high quality goods efficiently, wiped film molecular distillation isn't just another option anymore. It's becoming something most forward thinking businesses simply cannot afford to ignore if they want to stay competitive in today's market.

Pharmaceutical Industry Applications

API Purification at Lab and Industrial Scales

Wiped film molecular distillation plays a vital role in purifying Active Pharmaceutical Ingredients (APIs) within the pharmaceutical sector. The process helps ensure these ingredients comply with strict regulations that keep products safe and high quality. When manufacturers use wiped film molecular distillation, they get better results from their separation processes at scale. This approach saves a lot of time and money during production runs. Some industry data shows processing times drop around 40% when switching from older methods to this technique. These kinds of improvements explain why many companies are moving toward these advanced technologies. Better efficiency means consistent products come off the line every time, which matters a great deal in drug manufacturing where reliability counts.

Removing Solvents from Heat-Sensitive Compounds

Wiped film molecular distillation stands out because it gets rid of solvents without damaging those delicate heat-sensitive compounds that are so important when making medications. What makes this approach really valuable is how it keeps the active ingredients intact so they work properly once administered. The pharmaceutical industry has strict rules about purity standards, and this method helps meet those requirements by cutting down on leftover solvents in finished products. For companies dealing with FDA regulations or similar bodies around the world, maintaining low solvent levels isn't just good practice it's often mandatory. Patients don't think much about what happens behind the scenes, but knowing their medicines were made using advanced techniques like this builds confidence in both brand reputation and actual treatment effectiveness. That's why many smart manufacturers have started incorporating wiped film distillation into their workflow recently.

Concentrating Lipid-Based Drug Delivery Systems

Wiped film molecular distillation plays a key role in concentrating lipid-based drug delivery systems, making them much more effective for administering medications. The technology helps maintain consistent lipid concentrations and stability, something that matters a lot when creating these specialized formulations. When lipids vary too much in concentration, it affects how well drugs get absorbed in the body, which directly impacts their effectiveness. This precision makes wiped film distillation an important tool for developing reliable drug delivery methods that work consistently across different batches. Pharmaceutical companies need this kind of consistency because patients relying on lipid-based treatments expect predictable outcomes from their medication, especially when dealing with complex medical conditions where dosage accuracy is absolutely essential.

Cosmetics and Personal Care

Fragrance Compound Isolation

In the cosmetics world, wiped film molecular distillation has become really important for pulling out those delicate fragrance compounds. This kind of separation works wonders when trying to get top quality aromas straight from nature. Cosmetic companies find that switching to this method doesn't just make their products smell better, they actually get more bang for their buck too since the extraction rates go way up. According to people who know what they're talking about in the field, this technique beats old school approaches hands down. It manages to crank up production numbers without losing that authentic scent character, which gives brands a real advantage when crafting those luxury skincare lines customers love so much.

Concentrating Bioactive Skincare Ingredients

When it comes to skincare products, what really matters is how much active stuff they actually contain. That's where something called wiped film molecular distillation comes into play as a game changer. Basically, this tech lets manufacturers pack more goodness into their products without messing up what makes those ingredients work so well in the first place. Skincare companies can create formulas that hit harder because there's simply more of the good stuff inside them. People today want results, not just fancy packaging, and this approach delivers exactly that kind of punch. Plus, in our current beauty landscape where everyone seems to be launching yet another serum or cream, having products that actually do what they promise gives brands a real edge over competitors who cut corners on formulation quality.

Removing Oxidation Byproducts

Cosmetic products often suffer from oxidation byproducts that ruin both quality and how long they last on store shelves. Wiped film molecular distillation comes to the rescue here, basically acting as a cleanup crew for these unwanted chemicals. When companies apply this method, they get rid of impurities that would otherwise make products unstable or even unsafe over time. The beauty industry knows this well because regulatory bodies keep raising the bar on what counts as acceptable safety margins. Plus, people nowadays want their skincare and makeup to work better and last longer between purchases. For brands trying to stay competitive while keeping customers happy, investing in these kinds of purification techniques isn't just smart business it's practically essential if they want to avoid bad press from product recalls or customer complaints about premature spoilage.

Food and Flavor Extraction

Essential Oil Concentration

The wiped film molecular distillation method has become popular among producers looking to concentrate essential oils while boosting their flavor impact in food and drink products. What makes this approach stand out is how well it protects those sensitive aromatic molecules that give oils their distinctive character and scent. When we talk about extraction efficiency, this technique delivers much cleaner concentrations with stronger flavors compared to what most traditional methods can achieve. Food manufacturers really appreciate this because it means they get better tasting ingredients without compromising quality. Unlike conventional approaches, wiped film distillation cuts down on heat damage and prevents oxidation during processing, so the final product keeps all its natural qualities intact rather than getting degraded over time.

Natural Compound Isolation for Flavors

The food manufacturing sector has seen a growing interest in natural compound isolation through wiped film molecular distillation lately. Many producers want to offer their customers cleaner, more genuine flavors, so they're turning to this method. Basically, it pulls out those delicate flavor compounds from ingredients really carefully, which makes the end product taste better without needing any artificial stuff mixed in. People are definitely moving toward organic options these days, and market research shows the need for natural flavorings just keeps climbing year after year. Cutting down on synthetic additives helps create truly natural foods that fit right into today's health conscious lifestyle while also ticking boxes for eco friendly production practices that many companies now prioritize as part of their brand image.

Contaminant Removal in Edible Oils

Wiped film molecular distillation works well at getting rid of impurities in edible oils, which makes for better eating choices overall. When this technique is applied, it produces much cleaner oil by removing unwanted stuff left behind, making what ends up on our plates safer and actually more nutritious. Health minded folks definitely care about this kind of thing, but there's another benefit too the oil lasts longer on store shelves. What's interesting about the whole process is how it keeps those natural flavors intact while still making sure nothing harmful gets into the final product. People tend to trust brands that go through this extra step, and regulatory bodies look favorably upon companies following such strict purification methods.

Specialty Chemical Manufacturing

Solvent Recycling and Purification

For those working in specialty chemical manufacturing, wiped film molecular distillation has become almost essential when it comes to solvent recycling operations. What makes this technology so valuable is how it actually recovers and puts back into circulation those expensive solvents that would otherwise go to waste, cutting down on material expenses substantially. From an environmental standpoint, there's also the obvious plus side of generating far less waste overall, which means smaller landfills and cleaner air around industrial sites. Many companies are now looking at ways to green their operations, and incorporating this kind of solvent recycling isn't just good for the planet it also keeps their bottom line healthy in the long run.

Monomer Separation in Polymer Production

Wiped film molecular distillation stands out in polymer manufacturing because separating monomers really makes a difference in how efficient production can be. When manufacturers get that separation right, the whole polymerization process works smoother, which means we end up with higher quality materials at the end of the line. Beyond just making things run better, this technique actually ticks boxes for several industry specs that different polymer users need to meet. The ability to separate these components so precisely lets factories create polymers with exactly the characteristics they want. Think about it - automotive companies need certain durability levels while electronics makers require completely different properties. This kind of customization through molecular distillation has become pretty much standard across many sectors now.

Ultra-Pure Solvent Production

When dealing with chemical processes that demand extreme purity, wiped film molecular distillation really shines when it comes to creating those ultra clean solvents. These kinds of solvents matter a lot in things like pharmaceutical production or semiconductor manufacturing, where even tiny amounts of contamination can ruin an entire batch. Getting these high purity levels isn't just something companies need to do, it's pretty much table stakes across most industries these days. The regulations are so tight in fields ranging from food processing to advanced materials research that anything less than perfection just won't cut it. And this particular distillation technique does an amazing job at filtering out almost all impurities, which means labs and factories can consistently hit those tough quality benchmarks they're constantly being held to.

Future Industrial Applications

Bio-Based Polymer Refinement

Wiped film molecular distillation shows real promise for refining bio-based polymers, something that matters a lot for green manufacturing efforts. With so many industries moving toward environmentally friendly options right now, this tech actually helps improve how well these plant-based materials perform, opening doors for their use in everything from packaging to medical devices. When we get better at tweaking these polymer properties through distillation, we're basically helping manufacturers meet those tough sustainability targets that governments around the world keep setting. The process strengthens both the longevity and functionality of these biodegradable materials while cutting down on waste during production. For companies trying to balance profit with planet friendliness, this kind of technological advancement isn't just nice to have it's becoming essential as regulations tighten and consumer expectations evolve.

Semiconductor-Grade Materials Processing

Wiped film molecular distillation stands poised to transform how we process semiconductor grade materials, marking another step forward in our push toward precision manufacturing techniques. The electronics sector keeps demanding cleaner, purer substances as devices get smaller and more complex. When manufacturers adopt this particular distillation method, they can meet those tough specifications for semiconductors while knocking down impurity levels that would otherwise ruin delicate components. What makes this technology so valuable? It delivers consistency at microscopic scales something traditional methods just cant match. We already see improvements in chip reliability and circuit performance across multiple sectors from consumer gadgets to medical equipment. Looking ahead, companies integrating wiped film distillation into their workflows are likely to stay ahead of competitors who still rely on older purification processes.

Sustainable Production Advancements

Many industries keep sustainability at the forefront these days, and new advances in wiped film molecular distillation play a big role in cutting down energy costs while shrinking carbon footprints. As regulations get tighter around the globe, manufacturers need solutions that help them stay compliant without breaking the bank. What makes this tech stand out is how it actually improves energy efficiency during production. The process requires less heat than traditional methods, which means factories consume far less power overall. Plus, there's significantly less material wasted compared to older techniques. Companies adopting this approach not only cut expenses but also make real progress toward greener operations. We're seeing more food processors, chemical plants, and pharmaceutical firms switch to wiped film systems simply because they work better economically and environmentally speaking.

FAQs

What industries benefit the most from wiped film molecular distillation? Wiped film molecular distillation is beneficial in the pharmaceutical, cosmetics, food, and specialty chemical industries, among others.

Why is wiped film molecular distillation preferred for heat-sensitive compounds? This method is preferred because it enables the separation of heat-sensitive compounds without causing thermal degradation, preserving the integrity and efficacy of the compound.

How does wiped film molecular distillation improve product quality in cosmetics? It enhances product quality by effectively isolating key compounds like fragrances and bioactive ingredients, ensuring higher potency and stability.

Can wiped film molecular distillation contribute to sustainability in industrial applications? Yes, it supports sustainability by improving energy efficiency, recycling solvents, and reducing waste in various manufacturing processes.