Durability of Stainless Steel Molecular Distillation Systems

Reducing Replacement Costs Through Material Longevity

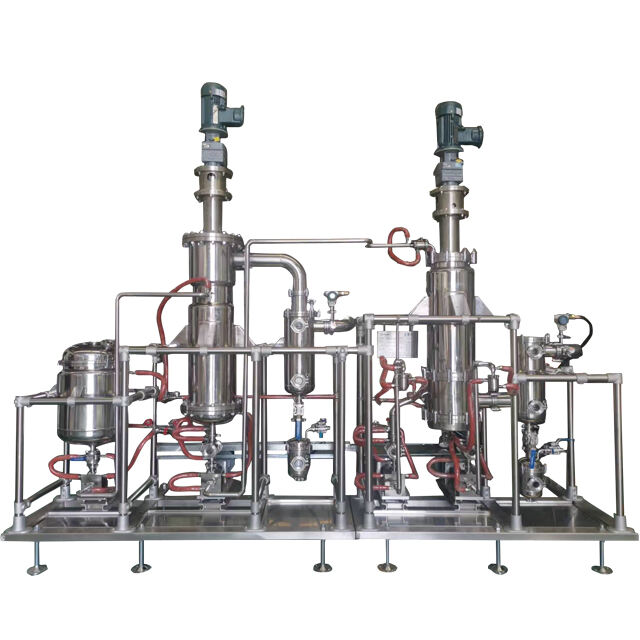

stainless steel molecular distillation equipment provides extraordinary durability, reducing replacement cost by reusing the molecular still. Its natural resistance tot tarnish and damage makes stainless steel an ideal material for use in daily life, glass or plastic which are easy to damage or wear can't compare! For instance, glass can break and plastics warp in high-temperature settings, but stainless steel does not compromise its structure.

Stainless steel is the best material compared to replacement. For example, glass and plastic apparatus are known to place additional demands for equipment replacements and repairs, such demands being extremely costly on the maintenance budgets. Meanwhile, adopting the durable stainless steel as the material of manufacture guarantees prolonged service life with little or no need to replace it, adding up to great ROI for industries using molecular distillation systems. These advantages are demonstrated by multiple case studies in different industrial sectors with large savings for maintenance. While the industry’s focus on economical and sustainable operations grows, stainless steel remains a sensible and economical solution, both from the financial and plant operation point of view.

Impact of High-Stress Resistance on Operational Lifespan

Stainless steel’s high-stress resistance is another important factor that makes it will live up to even more abuse than plastic locks. It can handle harsh environment such as high pressure, temperature variation, or corrosive surroundings without failure, and therefore is suitable for most harsh applications. Numerical data also confirms that stainless steel systems are up to higher work life in similar severe conditions to systems built with other materials.

Stainless steel has become the most common material of construction for short path and molecular distillation process systems According to industry experts, the use of stainless steel in the highest contaminant risk process areas is the best way to extend the life of your molecular distillation apparatus. Indeed, where industries are operating heavy duty environments, they may find that their stainless steel solutions decrease downtime and service interruption while increasing productivity and efficiency. Therefore, selecting stainless steel means not only longer life of the system, but also constant and trouble free operation that is absolutely essential in the industry.

Corrosion Resistance and Maintenance Savings

Minimizing Chemical Degradation in Aggressive Environments

Stainless steel is well-known for its quality anti-corrosive benefits and our range of products ensures the reduction of chemical weakening in even the most severe environments. Sectors handling harsh chemicals, (Pharmaceuticals, Petrochemical and Food Processing etc) the strength of stainless steel molecular distillation systems prove to be advantageous. This material is also quite resistant to corrosion, and reaction chambers and processing equipment will typically hold up over time. For example, stainless steel systems installed in chemical plants are able to withstand a wide range of harsh chemicals and can also operate under extreme temperatures and pressures. The outcome is not only a more efficient system but also cold, hard cash saved up in annual maintenance costs, thanks to reduced degradation compared to other materials.

Reduced Downtime from Corrosion-Related Repairs

Corrosion based repairs are time-consuming and reduce productivity as well as the additional financial burden to such repair. Corrosion is minimized when stainless steel, which has an excellent corrosion resistance, is used. Research has shown that stainless steel systems are many times less likely to cause shaker downtime than technologies made of plastic and glass. The shortened outages are essential to ensuring that operations are intact and that the risk and the financial loss of the downtime are minimized. Efficient corrosion control when using stainless steel results in a long service-life and continued operation of the equipment. With the use of procedures such as frequent cleaning and periodic inspection, the extend of corrosion resistance of stainless steel is maximized – defending it against breakdown and outages.

Energy Efficiency in Stainless Steel Distillation Systems

Superior Heat Transfer Mechanisms for Lower Consumption

Confidence Stainless steel is known for its excellent heat transfer, and can often save some money on your heating bills. Alloy materials like stainless steel conduct heat exceptionally well and that's important for maximizing the efficiency of energy usage in distillation processes unlike other, cheaper materials such as plastic. For example, when industries use stainless steel molecular distillation systems as a means for distillation, they enjoy the full effects of such benefits with lavish decrease in their energy bills. Moreover, these systems contribute to sustainability by reducing energy loss, making them the go-to solution in the pharmaceutical and petrochemicals industries, among others where efficient heat transfer is crucial to operations.

Thermal Conductivity vs. Energy Cost Reduction

The high thermal conductivity of stainless steel is instrumental in reducing energy consumption. By being able to dissipate heat more effectively, it is also more energy-efficient, because it requires less energy to keep at its optimal working temperature. Comparative studies show that significant cost reductions can be obtained in the case of stainless steel compared to other materials. And when businesses assess the potential for energy savings, they discover that replacing distillation equipment with the stainless steel model not only improves thermal management capabilities but also supports a drastic reduction in costs – which results in a much more positive bottom line!

Operational Reliability and Downtime Reduction

Robust Design for Continuous Industrial Processes

Robust and durable construction ensures the continuous operation of the system in industrial applications. Being close to indestructible and resistant to corrosion, it also holds up better than plastic or aluminum when subjected to industrial use, making it an incredibly versatile material for the industrial world. The failure rates for stainless steel systems are significantly lower when faced with continuous use, based on numerous studies. This dependability results in less down time over long runs, adding to productivity. Best practices for increased operational reliability By establishing adapted system configurations, optimised for the particular demands of various industrial applications, operational reliability can be maximised. This includes choosing the right stainless steel grade and paying close attention to fabrication so the base metal wont fail.

Mitigating Production Interruptions with Stainless Steel

Production stoppages can be reduced with the use of stainless steel systems that allow less shutdowns. Because of their long life and high tolerance to physical wear, these systems are also less likely to break-down, significantly reducing downtime. For example, many sectors have seen continuous production streams through the use of stainless steel distillation units which have minimized possibilities of sudden stops. The maintenance of such systems, however, involves proactive efforts to ensure that it will not fail prematurely. Preventative inspections and appropriate servicing can address the possible problems before struggling, Allowing the equipment to continue functioning effectively and experiencing less downtime. Maintenance recommendations include testing for corrosion during regular inspections, replacing worn-out components on a regular basis, and sanitizing systems to avoid contamination. Using these outlined strategies, industries can make good use of the trustworthiness of stainless steel to keep production running perfectly.

Cost-Benefit Analysis: Initial Investment vs. Long-Term Savings

Breaking Down Upfront Costs of Stainless Steel Systems

NBD-5510 Knowledge of the Start Up Costs of Stainless Steel Molecular Distillation Systems are Essential for Successful Purchase Decisions. This technology is known for its durability and long-life, which supports the relatively high initial cost when compared to conventional systems. The costs are mainly the result of the expenditure of high quality raw materials nickel, chromium, iron ores and so on and state-of-the-art machinery and equipment is utilized in fabrication. Citing industry professionals who believe in the long-lasting durability and performance of stainless steel systems, these firms agree that its lifecycle savings are big enough to justify the upfront costs. A look at some case studies illustrates how businesses achieve real operational efficiencies over the longer term with reduced operational cost and fewer replacements.

ROI from Reduced Maintenance and Energy Expenditure

ROI costs for stainless steel distillation equipment over a 5-10 year period must be factored in to consider economic feasibility. Many of these systems have incredible longevity and are less expensive to maintain and operate. When compared to alternative material systems, industry benchmarks have shown that stainless steel systems provide a higher ROI, mainly because of low maintenance requirements and improved operation. Cost analysis Graphs and tables have established the potential savings in different areas by using stainless steel solutions, proving them to be an economic option. In addition, the return on investment of stainless steel systems can be enhanced by the lower energy consumption and labour costs, which is congruent with the general trend towards sustainability and cost-effectiveness.

- Stainless Steel Molecular Distillation System: Explore case studies and industry benchmarks that highlight the financial gains from investing in stainless steel solutions for a clearer picture of their cost-effectiveness.

Sustainability Contributions to Operational Efficiency

Lowering Carbon Footprint Through Energy Optimization

Stainless steel molecular distillation appliances are essential for companies wishing to limit the environmental impact of their manufacturing processes. Their performance arises from their good energy-minimization properties that lead to lower emissions and superior energy optimization. Plants incorporating these systems have realized significant reductions in emissions.BENEFITS The environmental advantages of this technology have been demonstrated in a number of installations. Doing it right – best practices for the industry From an energy optimization perspective, best practice ensures a sustainable commitment is maintained by minimizing energy wastage and maximizing resource utilization. This will contribute not only to reduced carbon footprint but also towards making manufacturing greener.

Waste Reduction and Lifecycle Cost Implications

One of the incredible benefits of stainless steel molecular distillation units is the ability to minimize waste in your distillation process. The system are designed and built in materials ensuring a minimum of waste and provide long-term savings in operation and maintenance costs. LCC A Lifecycle cost analysis shows the significant economic advantages achieved from waste reduction through the use of stainless steel systems. Among those manufacturers who have "gone stainless," the savings are impressive and the move toward conservation and responsibility undeniable. Such statements clearly illustrate the impressive balance between performance and environmental credentials that stainless steel delivers.

FAQ

What are the main benefits of using stainless steel in molecular distillation systems?

Stainless steel molecular distillation systems provide significant advantages including durability, resistance to corrosion, and enhanced thermal conductivity, which result in reduced maintenance, energy savings, and overall operational efficiency.

How do stainless steel systems minimize downtime compared to glass and plastic systems?

Stainless steel systems minimize downtime due to their superior resistance to stress, wear, and corrosion, allowing them to maintain operational integrity and reduce the likelihood of repairs and maintenance interruptions.

Why is stainless steel considered energy efficient in distillation systems?

Stainless steel is considered energy efficient because of its superior heat transfer capabilities, which reduce energy consumption by minimizing the energy required to achieve desired process temperatures.

Does investing in stainless steel systems justify the initial high costs?

Yes, the initial high costs of stainless steel systems are justified by their long-term savings in maintenance, replacement, and energy expenses, presenting a compelling ROI over time.

How do stainless steel systems contribute to sustainability?

Stainless steel systems contribute to sustainability by optimizing energy use, reducing waste, and lowering the carbon footprint of manufacturing processes, which advances eco-friendly operational goals.

Table of Contents

- Durability of Stainless Steel Molecular Distillation Systems

- Corrosion Resistance and Maintenance Savings

- Energy Efficiency in Stainless Steel Distillation Systems

- Operational Reliability and Downtime Reduction

- Cost-Benefit Analysis: Initial Investment vs. Long-Term Savings

- Sustainability Contributions to Operational Efficiency

-

FAQ

- What are the main benefits of using stainless steel in molecular distillation systems?

- How do stainless steel systems minimize downtime compared to glass and plastic systems?

- Why is stainless steel considered energy efficient in distillation systems?

- Does investing in stainless steel systems justify the initial high costs?

- How do stainless steel systems contribute to sustainability?