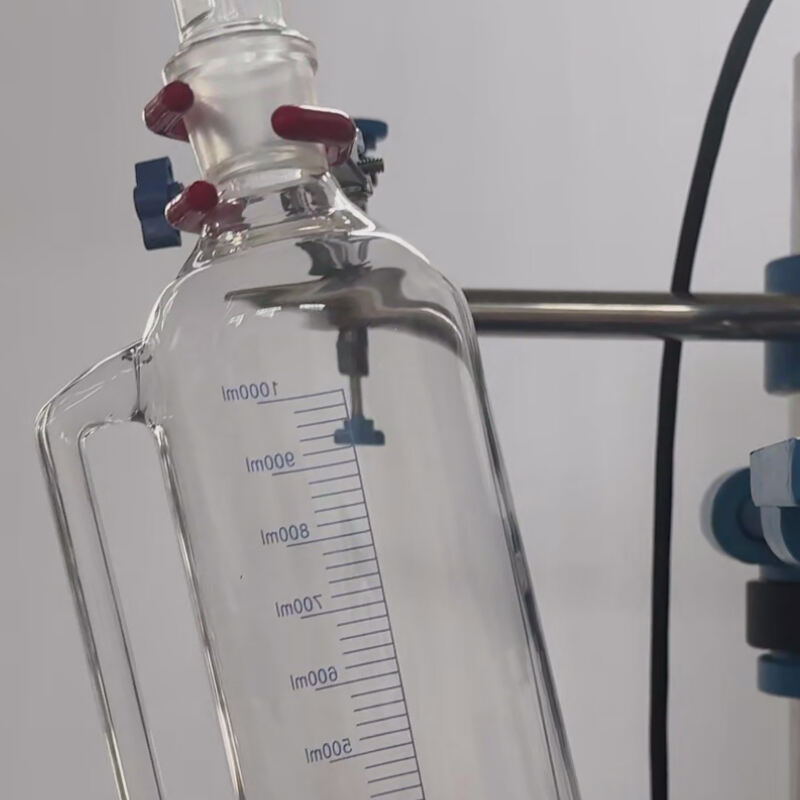

thin film evaporator

The thin film evaporator is a sophisticated piece of equipment designed for efficient and precise liquid processing. Its main functions include concentration, drying, and the removal of solvents from liquids. Utilizing a heating surface, it evaporates the liquid to create a thin film that enhances heat transfer and promotes rapid evaporation. Technological features such as the ability to handle heat-sensitive materials, a compact design, and ease of cleaning make it stand out. This evaporator finds extensive use in industries like pharmaceuticals, food processing, and chemical manufacturing, where it handles a wide range of applications from solvent recovery to the concentration of sensitive biological products.