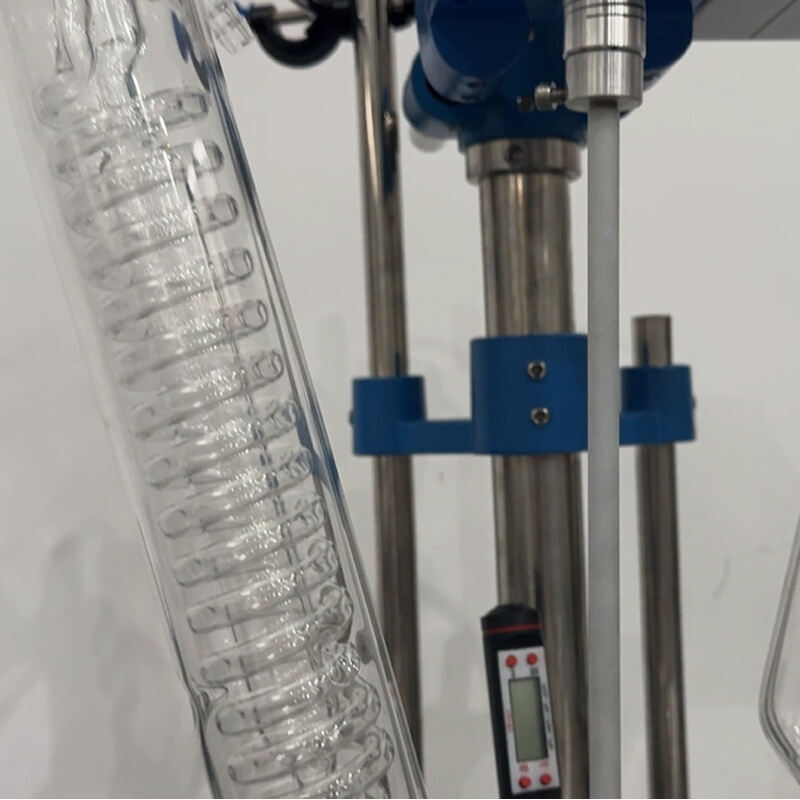

stainless steel fractional distillation equipment

The stainless steel fractional distillation equipment is a sophisticated piece of technology designed for the precise separation of liquid mixtures based on differences in boiling points. This equipment is engineered to deliver exceptional performance and reliability in various industrial settings. The main functions include heating the mixture to separate components, condensing the vapors, and collecting the purified substances. Technological features such as a precision temperature control system, corrosion-resistant stainless steel construction, and advanced fractionating columns ensure high purity yields and efficient operation. Applications span across the pharmaceutical, petrochemical, and essential oil industries, where the demand for pure, separated compounds is crucial.