glass short path distillation

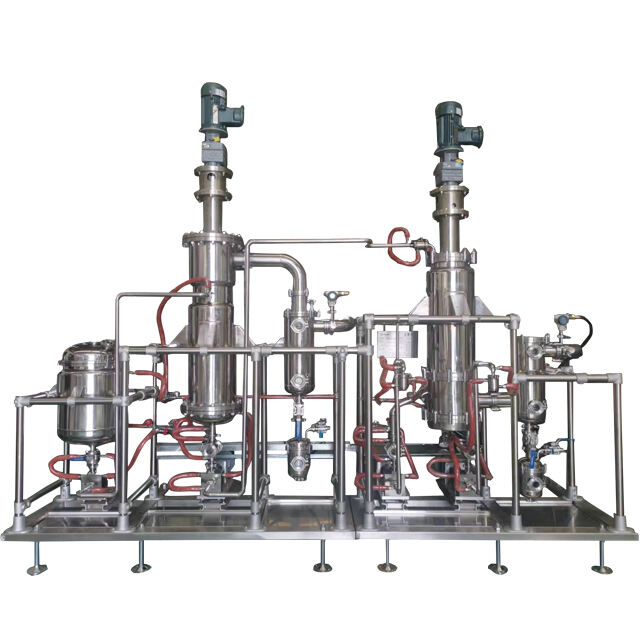

Glass short path distillation is a cutting-edge technique used for the separation of high-purity compounds. It operates on the principle of molecular distillation, which involves heating substances to create vapors that are then condensed to obtain purified products. The main functions of glass short path distillation include the removal of impurities, the concentration of volatile compounds, and the separation of substances with similar boiling points. Technological features of this system include a heated evaporation flask, a cooling condenser, and a rotating wiper that ensures a short path between the heating surface and the condenser, which is crucial for the process. This method is widely used in the pharmaceutical, chemical, and essential oil industries for producing high-quality products.