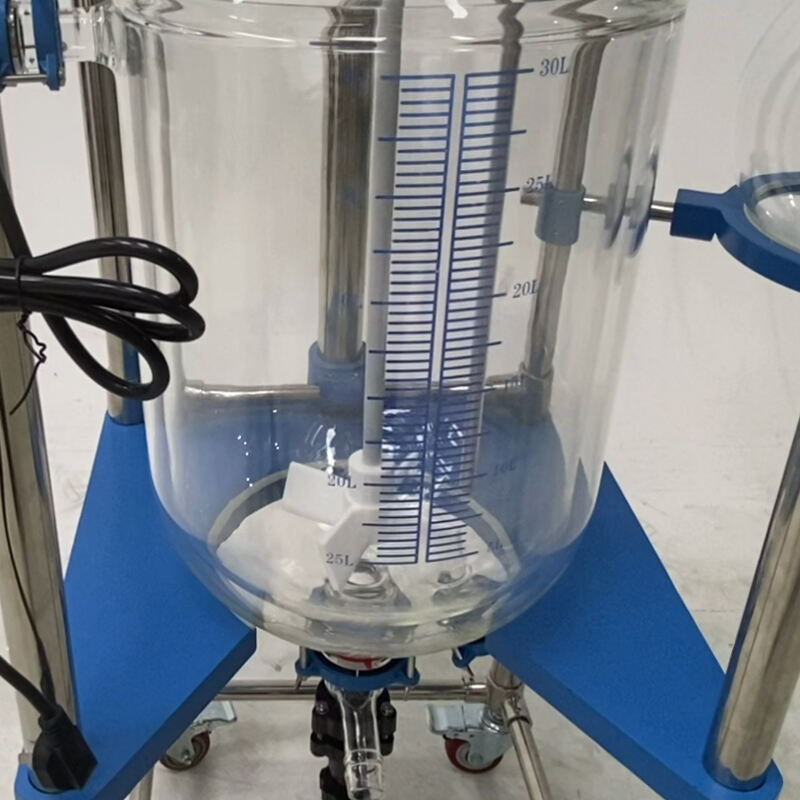

glass reactor

The glass reactor is a state-of-the-art piece of equipment designed for a variety of chemical processes. It is primarily used for reactions that require a controlled environment, such as synthesis, digestion, or extraction. The main functions of the glass reactor include mixing, heating, cooling, and circulation, which are facilitated by its advanced technological features. These features include a jacketed glass vessel that allows for even temperature distribution, a robust stirrer system for efficient mixing, and an array of sensors for precise monitoring. The applications of the glass reactor span across industries such as pharmaceuticals, biochemistry, petrochemicals, and environmental engineering, making it an indispensable tool in research and development as well as in production.