An explosion-proof glass molecular distillation system is a critical solution for the separation and purification of high-value, heat-sensitive, and solvent-based materials. As industries increasingly demand higher purity, safer operation, and gentle processing conditions, molecular distillation has become an essential technology—especially in pharmaceuticals, essential oils, nutraceuticals, and specialty chemicals.

This article explains how an ex-proof glass molecular distillation system works, its key design considerations, and how to select the right configuration for your application.

What Is Glass Molecular Distillation?

Glass molecular distillation is a type of short-path distillation performed under high vacuum, where the mean free path of molecules is longer than the distance between the evaporator surface and the condenser.

Compared with conventional distillation, molecular distillation offers:

Extremely low operating temperatures

Short residence time

Minimal thermal degradation

High separation efficiency for close-boiling components

Glass construction allows excellent chemical resistance, visibility, and flexibility, making it ideal for laboratory and pilot-scale systems.

Why Explosion-Proof Design Is Critical

Many molecular distillation processes involve flammable or volatile solvents, such as ethanol, hexane, or terpene-based compounds. In such cases, an explosion-proof (Ex-proof) molecular distillation system is essential to ensure safe operation.

Key safety risks addressed by ex-proof design include:

Solvent vapor ignition

Electrical sparks from motors or controllers

Static electricity buildup

Overheating of discharge lines

An explosion-proof system significantly reduces operational risk while complying with international safety standards for solvent handling.

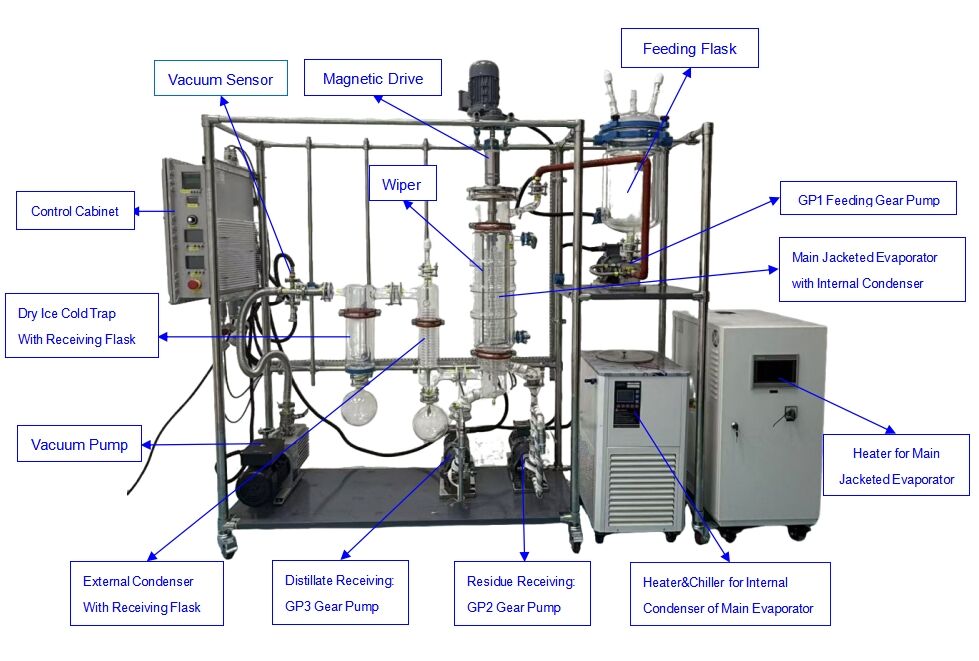

Key Components of an Ex-proof Glass Molecular Distillation System

1. Wiped-Film Evaporator

The heart of the system, where material forms a uniform thin film on the heated surface. PTFE wiper blades are commonly used to enhance heat transfer and prevent material buildup.

2. High-Vacuum System

A stable high vacuum lowers the boiling point of target compounds, enabling separation at mild temperatures and protecting heat-sensitive materials.

3. Explosion-Proof Drive & Pumps

Ex-proof motors for agitators and gear pumps

Explosion-proof electrical components

Independent pumps for light fraction and heavy fraction discharge

4. Jacketed Feed Tank

Ensures temperature control and safe handling of viscous or solvent-based feed materials.

5. Heated Discharge Lines

Heating tapes prevent solidification or crystallization, ensuring smooth and continuous operation.

Automation in Molecular Distillation Systems

Modern glass molecular distillation systems increasingly adopt automated operation, which offers major advantages:

Stable and repeatable process control

Reduced operator dependency

Improved product consistency

Continuous feed and discharge

Automated systems typically control:

Feeding rate

Wiper speed

Heating temperature

Vacuum level

Fraction collection

This is particularly important for pilot-scale production and process validation.

Typical Applications of Explosion-Proof Molecular Distillation

An explosion-proof glass molecular distillation unit is widely used in:

Essential oils & botanical extracts

(terpenes, cannabinoids, aromatic compounds)Pharmaceutical intermediates & APIs

(high-purity separation under GMP-friendly conditions)Nutraceuticals

(vitamins, lipids, omega oils)Flavors & fragrances

(heat-sensitive aroma components)Specialty & fine chemicals

How to Choose the Right Molecular Distillation System

When selecting a glass molecular distillation system, consider the following factors:

Material properties

Boiling point, viscosity, solvent content, thermal sensitivityProcessing capacity

Laboratory, pilot-scale, or small-scale productionSafety requirements

Need for explosion-proof motors, controllers, and pumpsAutomation level

Manual vs. semi-automatic vs. fully automated systemsFuture scalability

Ability to scale up to larger evaporator diameters (e.g. 6 inch, 8 inch)

Conclusion

An explosion-proof glass molecular distillation system combines gentle separation, high safety standards, and process efficiency. For industries working with volatile solvents and high-value compounds, it provides a reliable solution for purification, concentration, and fractionation—without compromising product quality.

With proper design and automation, glass molecular distillation systems are ideal for R&D, pilot testing, and early-stage production, offering a clear path toward industrial scale-up.

Looking for a Customized Molecular Distillation Solution?

We provide tailor-made glass molecular distillation systems, including explosion-proof configurations, automation options, and complete auxiliary equipment integration.

? Contact us: inquiry@valuenindustrial.com

Our technical team is ready to support your application.

Table of Contents

- What Is Glass Molecular Distillation?

- Why Explosion-Proof Design Is Critical

- Key Components of an Ex-proof Glass Molecular Distillation System

- Automation in Molecular Distillation Systems

- Typical Applications of Explosion-Proof Molecular Distillation

- How to Choose the Right Molecular Distillation System

- Conclusion